Agriculture, Sustainability March 01, 2023

Beyond Hay

.

Protein process converts grass for non-ruminants.

As the expression goes, hay is for horses—or for ruminants, which also have the ability to digest the fibrous lignin that makes up much of the material in grass. But a new Danish venture is turning that old wisdom on its head by separating the components of grass to create a fine, granular protein feed for pigs and poultry—and someday, for people, too.

BioRefine Denmark is owned by three major Danish cooperatives in the seed and feed business: DLG, DLF, and Danish Agro. The joint venture works closely with massive pork co-op Danish Crown and dairy giant Arla, notes BioRefine CEO Vagn Hundebøll.

"Let's say we have the input side and also the output side as owners of this program," he says.

BioRefine's feedstock is cut from mixed stands of festulolium—a cross of perennial ryegrass and tall fescue that yields nearly four times as much protein as corn stover—alfalfa and red and white clover. The legumes in the mix fix nitrogen, while locally sourced manure meets the rest of the crop's nutrient needs, allowing all the material going into the plant to qualify as organic.

"All this is organic, which also goes well with development, especially in Scandinavia where more and more consumers want organic milk, meat, whatever," Hundebøll points out.

The company estimates that growing the grass/legume blend reduces nitrate leaching by 70 to 80% in western Denmark's low-fertility, sandy soils, and also sequesters 1 metric ton of carbon per hectare every year. As Danish farmers struggle with water quality regulations and an aggressive carbon capture agenda, those benefits are important.

"It's very much on top of mind of the politicians," Hundebøll says.

"We have this area where we're not really allowed to do any farming, but we can introduce this grass and alfalfa," he adds. "Our next [processing] plant might well be in this kind of sensitive area where we can get some support to help solving a problem of environmental issues and bringing some valued products out of it."

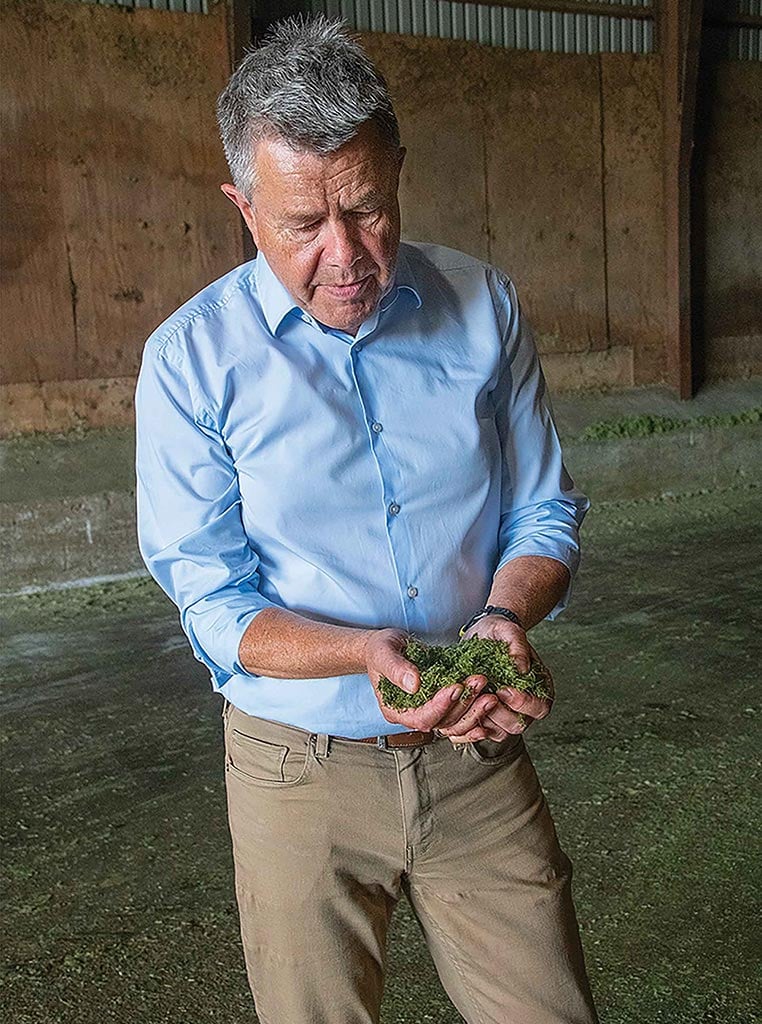

Above. CEO Vagn Hundebøll says BioRefine protein will compete with soybeans. BioRefine’s process includes washing, pressing, heating, and centrifuging grass to isolate its proteins and dry them into a powder. Hundebøll says the company is exploring uses for fiber byproducts. When scientists figure out how to minimize the protein powder’s bitter flavor, it could also be used in human food.

Contracts. Contracted farmers plant and manage the crop, and BioRefine crews harvest and haul it. With 5 to 6 cuttings over a 6-month season, BioRefine promises its growers financial returns equivalent to what they would net by growing cereals.

At the plant near the village of Kærup, trucks deliver cut grass within 6 hours of harvest (or even less on hot days). The vegetation is finely chopped, washed to flush the first fraction of protein from the fiber, then squeezed in a screw press to extract more liquid. That fluid is heated to 89 degrees C (192 degrees F), separated in a centrifuge, and flash-dried into a bright-green powder.

Home-grown protein. In all, 55% of the mass that enters the plant ends up in 500 kg (1,100-lb) bags as protein. Hundebøll says the company is working on uses for the lignin fiber byproduct—so far, one promising outlet has been egg cartons. The eggs inside those cartons feature bright-yellow yolks, a benefit of feeding BioRefine's protein to hens.

If it sounds like BioRefine protein is lining up to replace soy protein...well, it is. Many Danes associate soybeans with deforestation in the Amazon. Remind them that not all soybeans come from Brazil and they reply that they are not excited about buying GMOs, either. The push is on to find home-grown protein.

"We see some dairy companies in Denmark claiming that, 'Next year we will only produce milk from cows that have been fed by proteins grown locally in Denmark,'" Hundebøll says.

Last year—its second season—BioRefine was running at its full annual capacity of 10,000 tons, drawing grass from 3,000 hectares (7,400 acres). Co-op staffers are scrambling to improve every step, including higher-protein genetics, varieties that yield more consistently across the season, and process efficiencies in the plant.

That's life on the cutting edge.

"We are not really at the end of our journey, but we have to take our own steps here because there are not really any colleagues or competitors that we can go and learn something new on the technology," says Hundebøll. ‡

Read More

AGRICULTURE, RURAL LIVING

Rootbound Farm Grows Deep Organic Roots

Committed to taking local eating beyond corn and tomato season.

AGRICULTURE, AG TECH

Tech@Work

John Deere's AutoPath™ helps take the guesswork out of guidance.