We just made the best S7 yet. Automatically.

Last year, we re-imagined what the S7 Combine could do. We gave it more brains to bring crops in faster without sacrificing quality. We gave it vision to see ahead and automatically adjust speed to crop volume. And we made combine settings as easy as one, two, three. But that was only the beginning. This year, we added more harvesting smarts. We gave it hands-free automatic turning. We made it easy to share real-time grain weights with your entire harvest team and we automated the unloading process. We even found time to add a better instructional seat. Together, it all adds up to the most advanced and capable S7 Combine ever built.

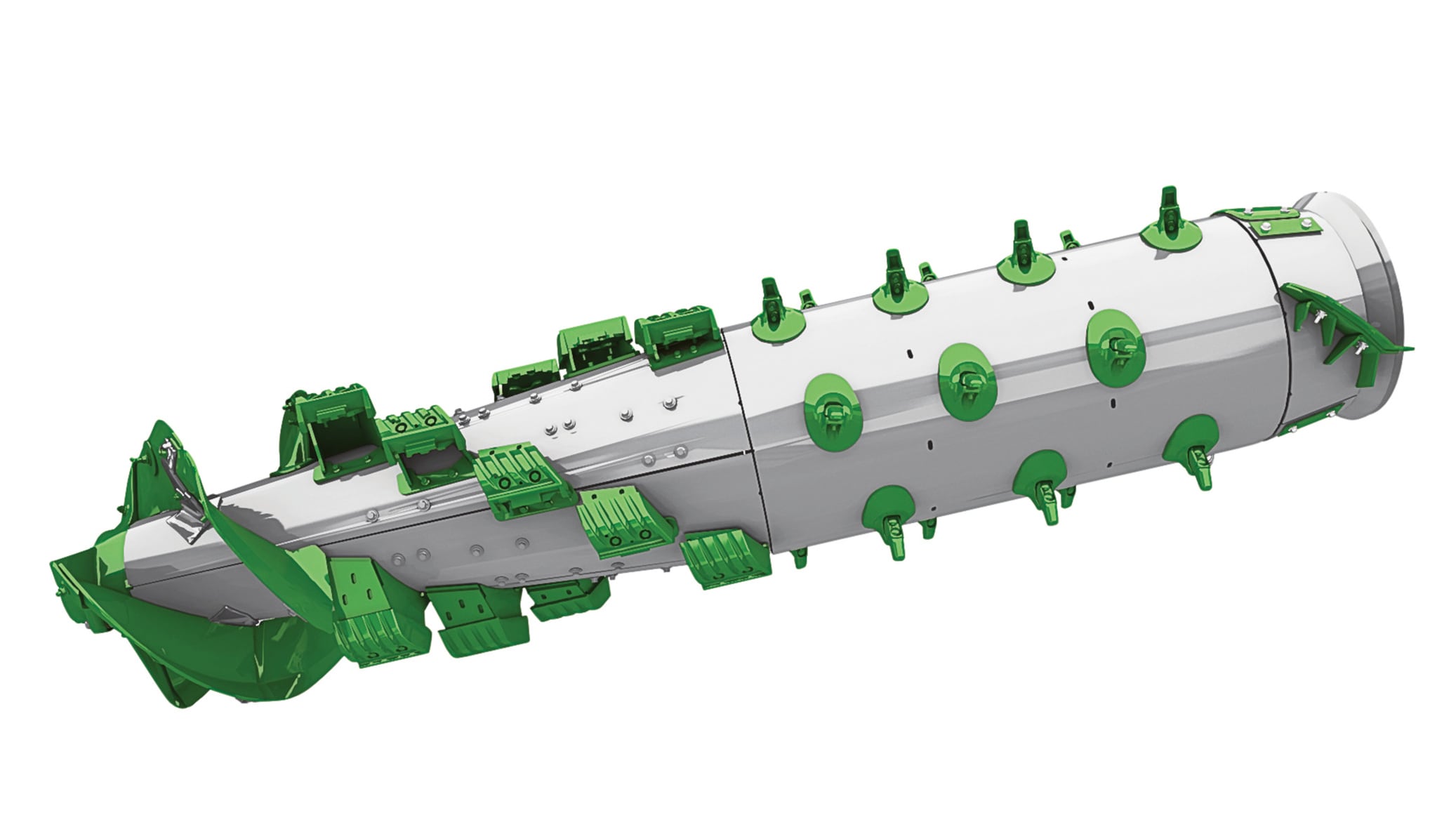

A smarter combine deserves a smarter head.

We raised the bar on our draper lineup — again. We gave it a 3-piece reel to maintain consistent reel-to-cutter bar distance — even in rolling and uneven terrain. And a cam reel gives you aggressive crop engagement in ALL crops.

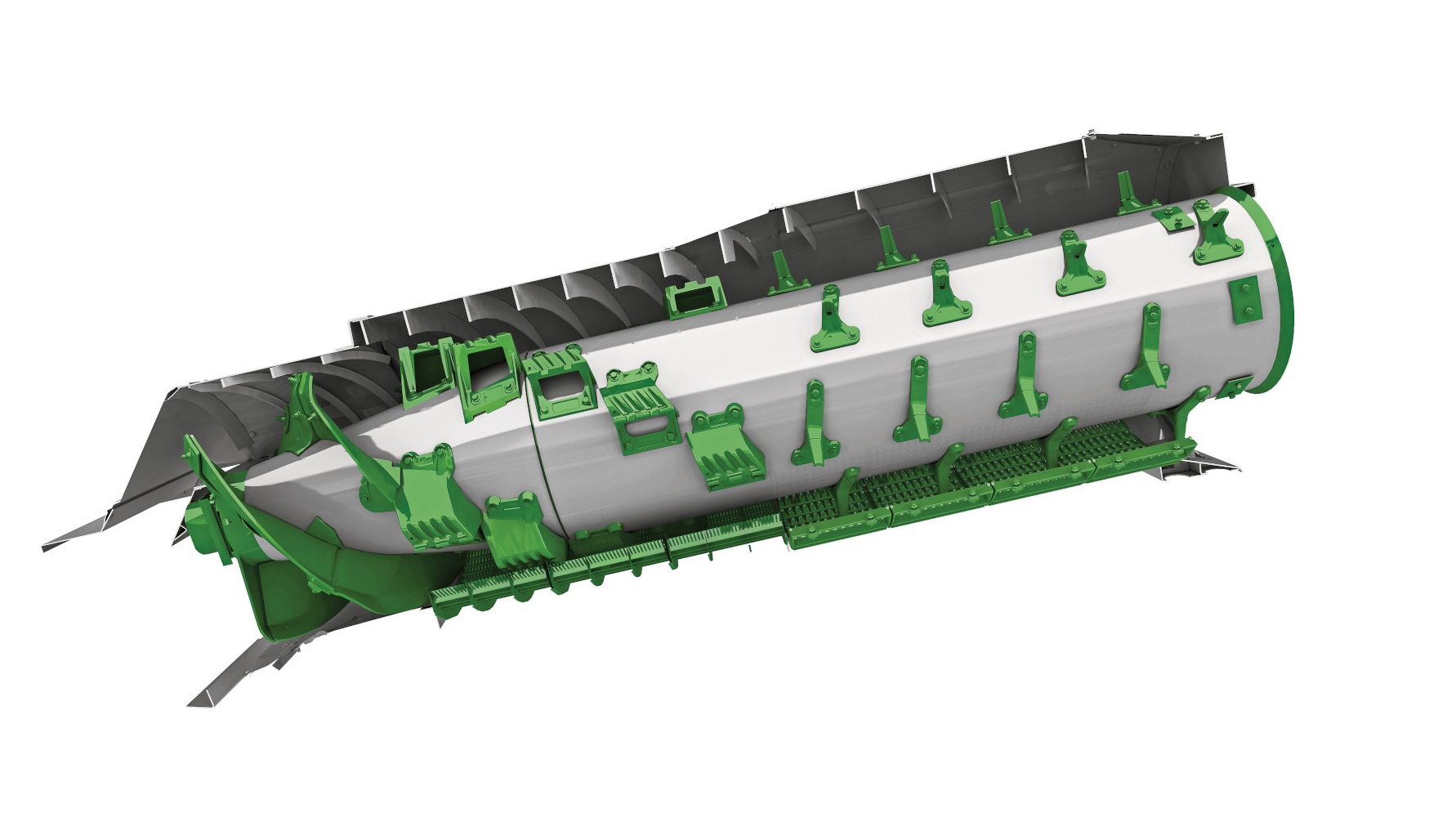

Meet your mean, green, grain-eating machine.

Automation

Predictive Ground Speed Automation

Increase productivity by up to 20%* with Predictive Ground Speed Automation1, included in the optional Ultimate Technology Package. Using two forward, cab-mounted stereo cameras, the S7 constantly measures crop height and volume — while pre-harvest satellite field images generate a predictive field map. The combine takes this data and automatically adjusts ground speed BEFORE entering changing crop areas. Feel confident to maintain peak feed rates all day long, even in inconsistent crop conditions.

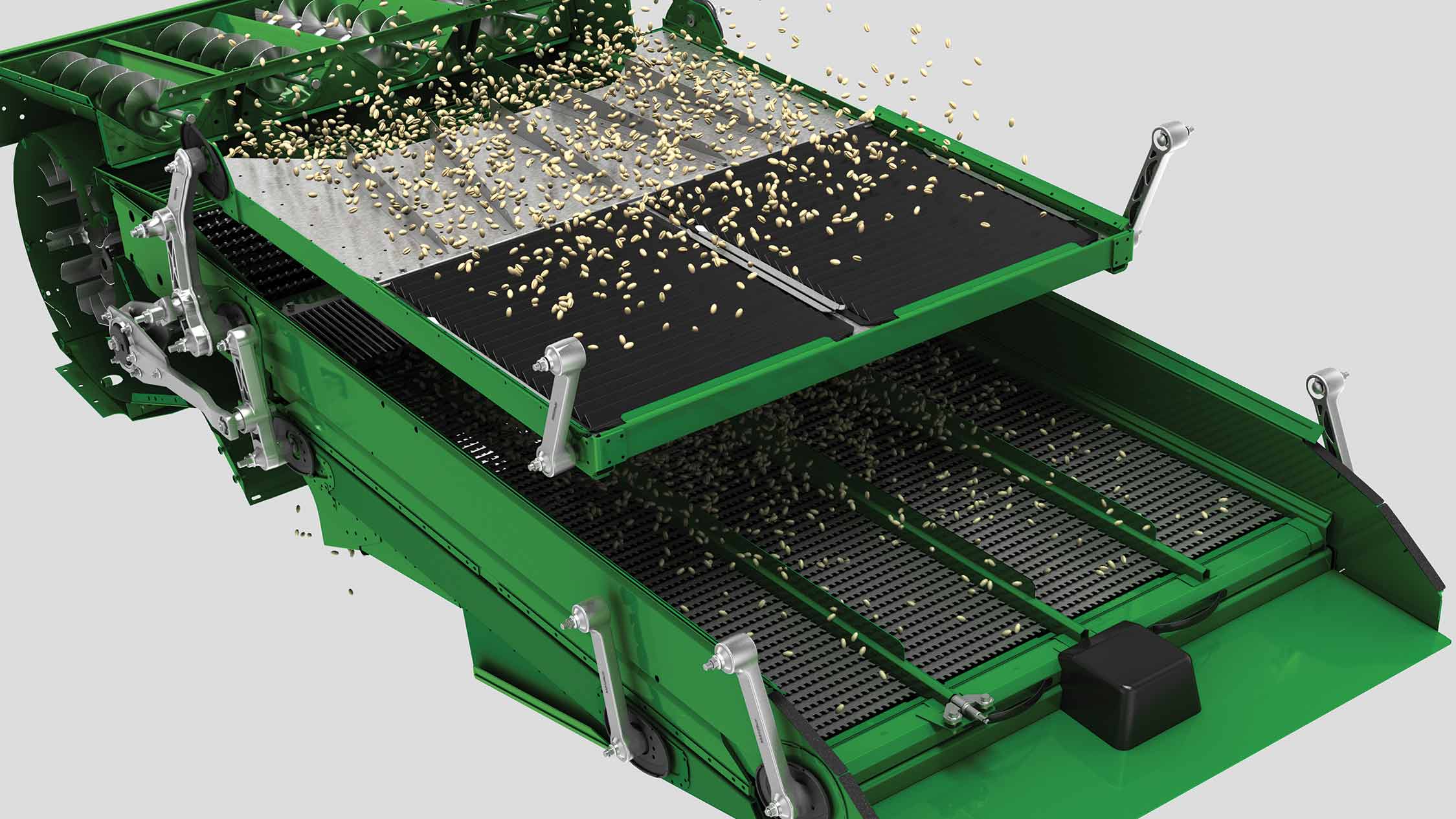

Harvest Settings Automation

Harvest Settings Automation1 – included in the Premium and Ultimate Technology Packages – makes it easier than ever to set the specific outcomes you expect. Using your G5Plus Display, simply set acceptable limits for grain loss, foreign material, and broken grain. Once set, the combine automatically adjusts itself to deliver the performance you want. No more manually adjusting rotor speed, fan speed, and concave, chaffer, and sieve clearances. The combine does it for you according to outcomes you've already prescribed. That gets you into crops faster and reduces the things you have to constantly monitor. When set limits are exceeded, your display shows you where the setting adjustment is being made and why.

AutoTrac™ Turn Automation with Header Raise/Lower

COMING SOON

More and more operators are discovering the hands-free confidence AutoTrac Turn Automation (ATTA) gives them during in-crop turns. But they still had to remember to raise and lower the header. Not anymore. Coming soon we're adding the capability to automatically raise and lower your header. Always at the right time. Always at the right place. That's one less task to worry about, so you can concentrate on more important things. Check back later or ask your John Deere dealer for more details.

Power and Productivity

John Deere JD14 13.6L engine

Built for ag work in the toughest conditions. The turbo-charged, 830 cu in. power plant not only gives you maximum-rated power at lower engine RPM, but it also boosts maximum torque by up to 10%1. More efficiency. More productivity. Less fuel. That's what we call smart power.

10% more max torque1

10% less fuel used1

Comfort and Control

A bigger, more comfortable cab

The same cab on our industry leading X9 Combines is the same one we put on the S7. Quieter than previous models, with improved visibility, this cab gives you all-day comfort for all-day work. With an integrated G5Plus CommandCenter™ Display, an integrated StarFire™ Receiver, and a larger corner display, you get more visibility and more control. That's how you keep operators at their best... all day long.

Connected Technology

G5 Advanced Package

More automation means more productivity and less stress. That's what you get with the optional G5 Advanced Package, which bundles five of our most advanced guidance and automation technologies into an annual license3. That gives you not only a lower up-front cost, but also technology that gets better over time, as you'll get automatic access to new features as they are released.

Integrated G5Plus CommandCenter™ Display

Get more harvest data on the larger, faster and clearer G5Plus Display. See more and easily make machine adjustments with a 35% larger screen4. Start harvesting quickly with faster boot times4. And catch every detail on the 1080p HD touchscreen, in any environment.

StarFire™ Receiver with SF-RTK

The integrated StarFire™ Receiver with SF-RTK delivers accuracy within 2.5 cm. A multi-constellation satellite signal gives you up to 73% faster pull-in times2. And long-term repeatability minimizes guidance line, coverage, and boundary drift year after year to maximize your AutoPath™ passes.

Maintenance & Reliability

Our equipment is supported by one of the most responsive dealer networks in the business.

John Deere Connected Support™

S7 Combines come with built-in technology to sense potential issues and alert you - or your dealer - when there's a concern. With Connected Support, you get Remote Display Access and Expert Alerts. You can monitor machine fuel levels, location history, receive alerts and view the in-cab display remotely.

John Deere Protect Plans

Annual Expert Inspections and regular scheduled maintenance, coupled with PowerGard™ extended warranty will help ensure "like new" performance and uptime of your combine and reduce unexpected expenses for up to 36 months.

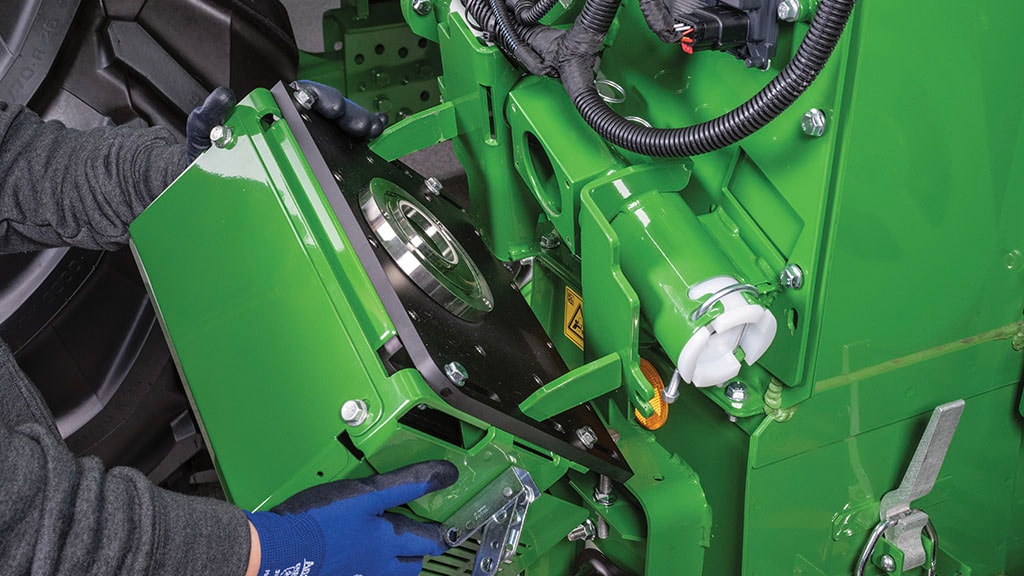

Inspections

Keep your combine in tip-top condition with comprehensive inspections. Our highly trained technicians will replace worn parts and tune up other key areas.

Boost your current combine's performance

Looking for a Precision Upgrade? Need a new part? See what we've got to keep your harvest running smooth.

You Also May Be Interested In

You May Also Be Interested In

*Claimed based on same model running in the same crop over the same amount of acreage, one with Predictive Ground Speed Automation on and one with it off.

1Requires ProDrive™

2Compared to previous models

3License fees required

4Compared to previous Generation 4 Displays