Agriculture, Specialty/Niche September 01, 2023

Green on the Walls

.

Vertical farming takes off at Leafy Greens Farms.

The lettuce farm of the future resides in a non-descript, 8-foot wide and 40-foot long shipping container just outside Pittsburg, Kansas.

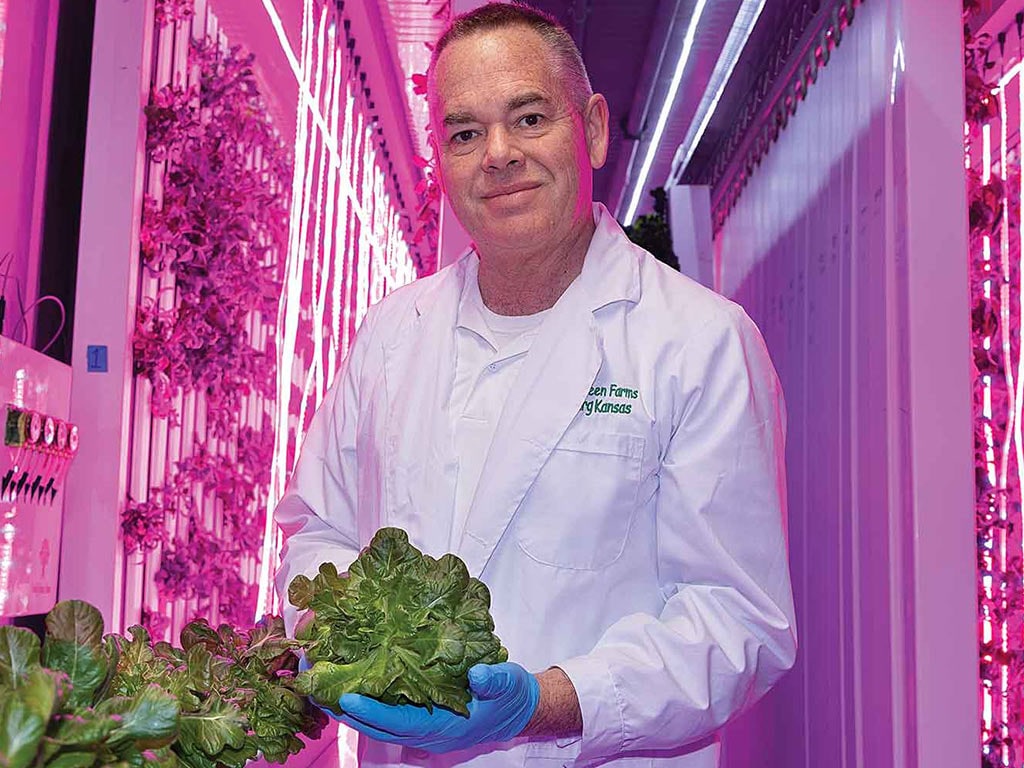

That's where Brad Fourby and the team at Leafy Greens Farms are producing two acres worth of fresh lettuce and herbs each year, while using a fraction of the space, water, fertilizer, and labor that traditional farms require.

How this farm exists—and in Pittsburg, of all places—is quite a story.

Three decades ago, Fourby lived in Sacramento, California, and worked in the energy industry. One day he was at home and the television was on as background noise. A "where are they now" type of show was on and a former celebrity was talking about his new job: raising fish in freshwater pens.

"I stopped what I was doing to watch that show," he recalls. "For whatever reason, that clicked with me."

He could not figure out how to make a living fish farming in small spaces. "But you give someone 40 feet, and all the numbers begin working out," he says. He began a consulting business called Innovative Farms to assist farmers growing fish and with hydroponics. He retained his day job, through which he knew the owners of Energy Group Consultants, based in Pittsburg.

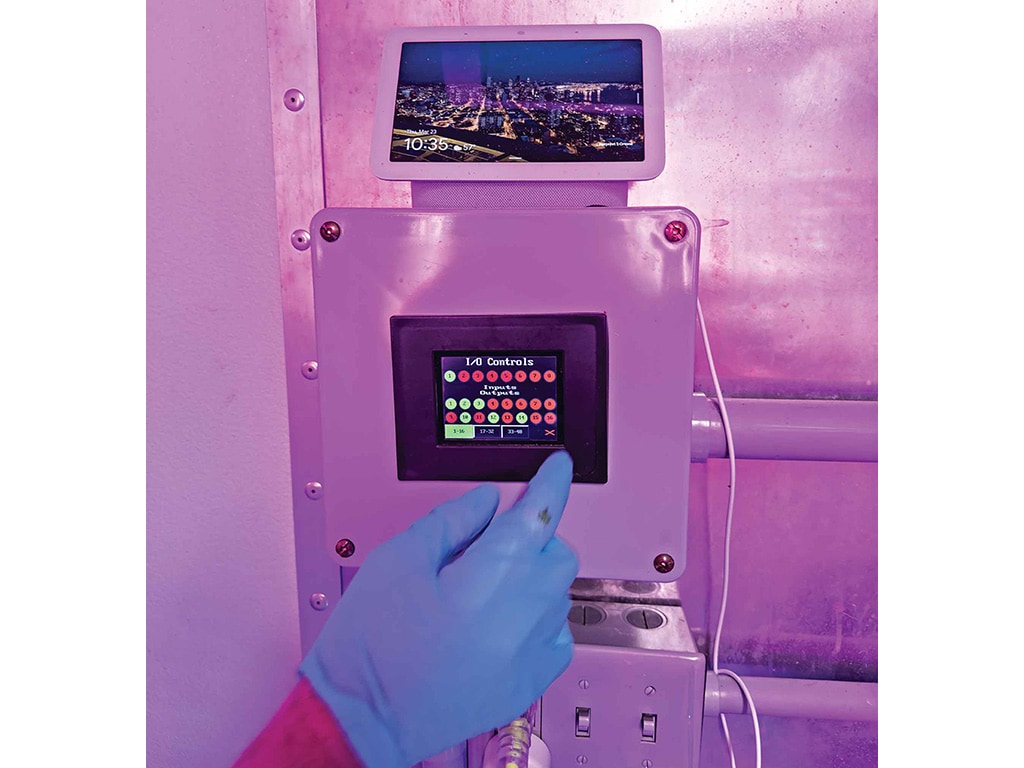

Above. Brad Fourby, founder of Leafy Greens, says a converted container farm can produce as much produce as two acres of land. It takes five weeks from seed to harvest for most of the produce. Heather Horton, owner of TOAST Restaurant in Pittsburg, Kansas, says Leafy Greens provides a consistent supply of quality produce. A non-descript cargo container houses roughly 2,500 plants and 5,000 seedlings at any time in this Leafy Greens Farm. Harvest occurs every week. A farm costs about $100,000, depending on options. A technology hub controls temperature, humidity and other factors in a Leafy Greens Farm.

Food desert. In 2020, they convinced him to move to Kansas and begin Leafy Greens, hoping to make a dent in the need for locally-grown, healthy food. The area was considered a food desert: limited access to affordable and nutritious food.

Together, they bought a farm from Freight Farms, a Boston group that sells kits to refurbish containers into farms. Fourby left his job to run Leafy Greens full time. The first farm was delivered in 2021.

"You talk about a guy who had everything on the line. When I walked into that container for the first time, opened the door and saw all these parts that needed to be put together, I thought I better put on a happy face because I didn't know what I was getting into," he recalls.

He threw himself into the business, and now Leafy Greens has three farms, and a portable prototype only about 15-feet long.

Each farm is a bit like a machine. To the left of the walk-in door is a stainless steel bench where towers of produce are prepared. Each of 256 polyurethane "towers" contains a mix of peat moss and cocoa fiber, into which seeds are planted. These towers hang from the ceiling and can be easily moved. Water is pumped to each tower, and plants are irrigated with drip nozzles and a wick system for six or seven minutes each hour; the limited runoff from which is reused.

Temperature and humidity are controlled via an app on his smartphone, with a sophisticated controller in the trailer. While insect or disease pressures are possible, the likelihood is very low due to the closed-loop system, Fourby says.

Roughly 2,500 plants in various stages of maturity are growing at one time; nearly 5,000 seedlings are in pots waiting to be transferred. From seed to harvest takes 10 to 12 weeks, depending on the produce. Towers are loaded with various kinds of lettuce, Swiss chard, basil and spinach. The list of new products grows constantly. Some work (Wasabi arugula); some don't (tomato fruits break the stems).

Weekly harvest. "Instead of getting just one or two big harvests, I take a harvest every single week," Fourby adds.

It's not always easy. "Four times I've come into work and these plants were dead. That's an 'oh geez' feeling," Fourby says. "Luckily, I've been able to catch it in time and everything comes back to life. But I can only imagine what farmers have to go through all the time."

The farm has built a customer base through community outreach and by tapping into local and retail markets.

"People are looking for good food," Fourby says. "They will pay more money for premium lettuce if it is crisp and flavorful."

"We have a proclivity to offer products that are better for you, raised locally by the right people," says Matt DeMoss, owner of The Meat Shed, a butcher shop, meat market and deli in Pittsburg that offers Leafy Greens salad mixes. "We get it the day after it's picked and it lasts longer."

Pittsburg restaurateur Heather Horton aims to source local ingredients for her downtown eatery, called TOAST. "In the winter, when we can't get fresh greens and the supply dries up, he's able to meet our demand. We're able to get nutritious produce all year long. That's pretty exciting."

At the outset, Leafy Greens appealed to the Kansas Health Food Initiative for $15,000 in seed money, and joined Live Well Crawford County to address food insecurity. The farm donates excess fresh produce to area food pantries, also providing tips on how to best use the produce.

"I've been told multiple times this won't work, that people don't care about healthy food," Fourby says. "I have found that to be completely opposite." ‡

Read More

AGRICULTURE, SPECIALTY/NICHE

At a Canter

Mounted archery is the ultimate team sport.

AGRICULTURE, FARM OPERATION

Keep the Vegetables Coming

A deep winter greenhouse provides good winter growing conditions.