Resources

Products in Action

How many ways can you use 200 kW of clean 3-phase power?

JDE is developing a liquid cooled, high power density AC Sine Wave Filter.

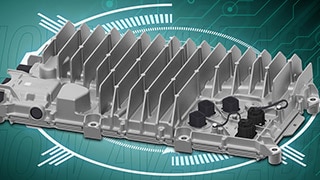

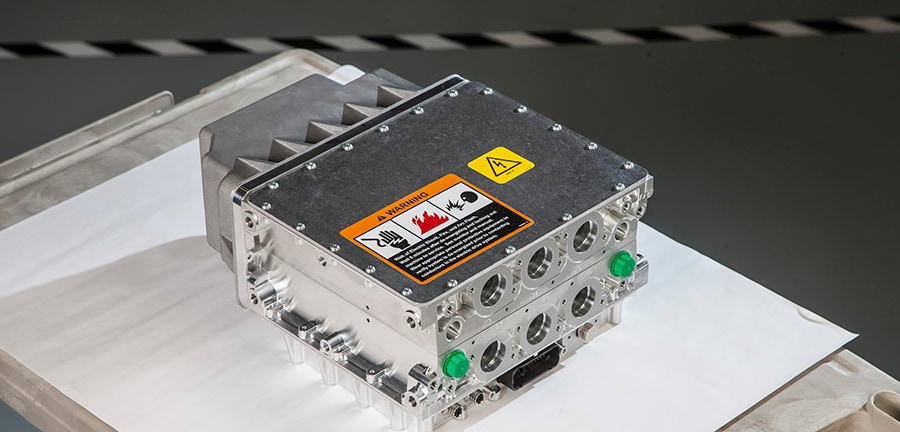

All-In-One: The PD400 Dual Inverter

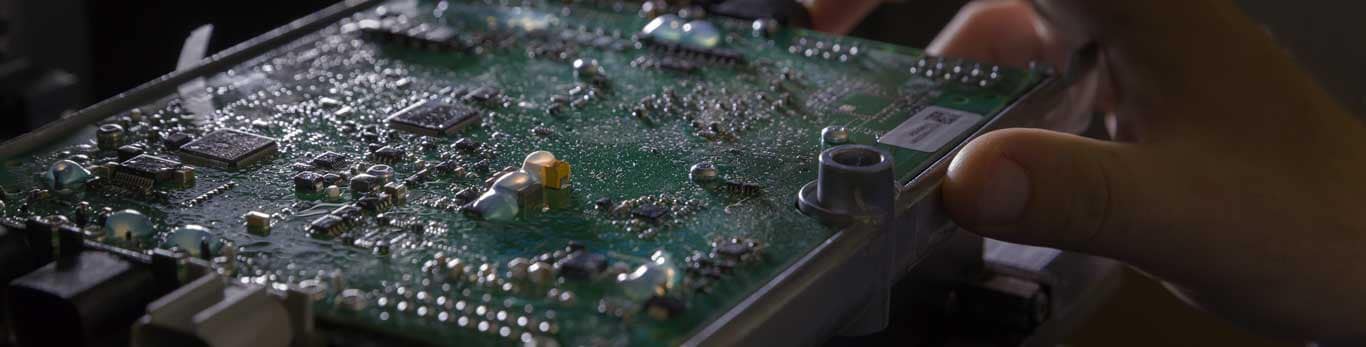

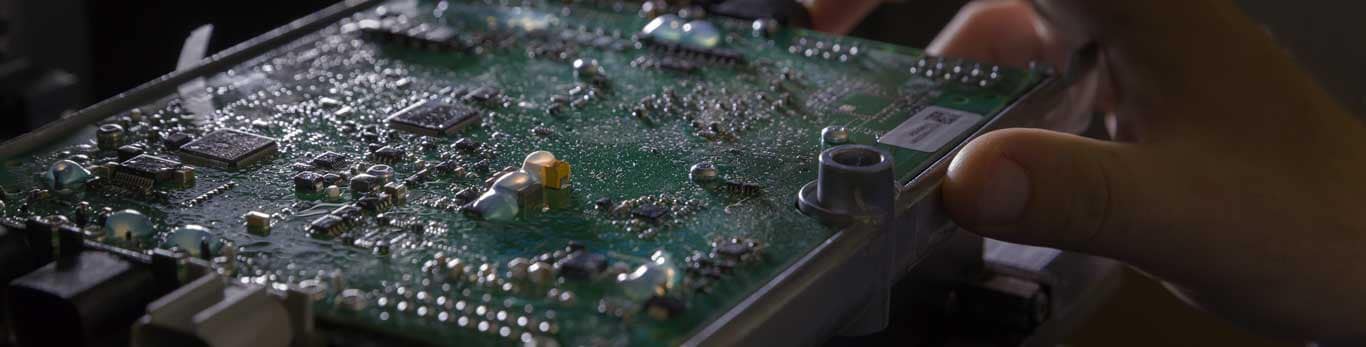

Compact and efficient machines are critical to heavy-industry customers’ success. With the numerous complex systems and their many parts, it is no surprise that utilizing space efficiently can be a challenge for engineers. The newly released PD400 modular inverter from John Deere Electronics (JDE) provides space saving and flexibility to system designers with a solution for high-voltage / high-power hybrid electric vehicles

Case Studies

System Architecture Thomas Built Buses

When one of the leading school and commercial bus manufacturers in North America needed help to modernize their electrical systems, they turned to John Deere Electronics.

Case Study: Mitigating Resonance in Multiple Inverter Systems

Advances in electrified vehicle design aren’t impacting only consumer vehicles, but are also beginning to influence system design and development in on- and off-highway heavy equipment.