In-House Excellence

At John Deere Power Systems, we’re always looking for smarter ways to deliver what our customers need and want. Rama Motori, the John Deere engine distributor in Italy, took this approach to the limit by transforming its mindset and its production department. The result is premium service for OEM and end customers — greater design flexibility, more consistent quality, and quicker delivery — plus a wealth of operational and business benefits for Rama.

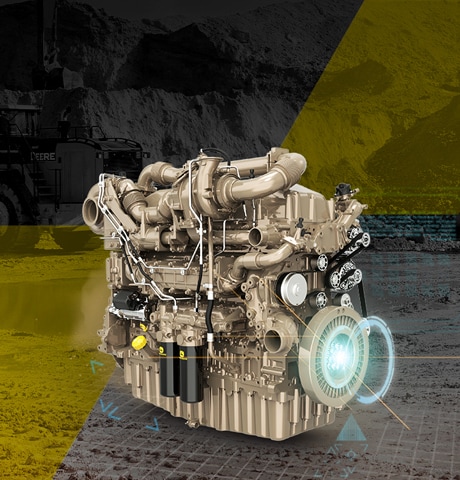

John Deere Power Systems delivers on-time, customized quality

In an ever more demanding power solution industry, John Deere Power Systems is committed to meeting customers' three fundamental needs: customization, on-time delivery, and premium quality. Customization means delivering a complete, integration-ready power solution tailored to their specific application. On-time delivery is important for everyone, but for OEM customers it is crucial for planning production schedules and meeting their own customers' delivery demands. And in power solutions, "quality" means robust, reliable, and durable, while also meeting all relevant emissions standards.

Rama Motori is a long-time distributor of John Deere marine and industrial engines for Italy. To meet OEM customer needs, it goes far beyond simple supply. Rama aims to provide complete engine solutions, supported throughout their lifetime, from engine selection through customization, testing, integration, and application trials to after-sales service.

This includes assembling and customizing John Deere 4- and 6-cylinder engines for customers' specific applications. Customization can range from adding simple mounting brackets to integrating large radiators and aftertreatment systems.

By moving the emission reduction technologies to a different position, Energreen was able to reduce the size of the tail, increasing safety in roadside operations.

Project Efesto: transparency, tradition — and modern know-how

In 2020, Rama made the decision to switch from relying on a local supplier for modifications to carrying out assembly and customization work in-house. "When the COVID-19 pandemic struck, we took the opportunity to run a SWOT analysis and identify our goals and the tools we needed to achieve them," explains Andrea Bertolini, operation manager.

"The CEO, general manager, technical director, facility manager, and operation manager together reviewed suppliers, internal processes, software, and equipment needs. Based on our deliberations, we decided to build a new assembly line at Rama’s headquarters in Reggio Emilia."

They called the project "Efesto," which derives from Hephaestus, the Greek god of blacksmiths, craftsmen, artisans, sculptors, metals, metallurgy, fire, and volcanoes. "We thought it was a suitable name to protect and inspire the mechanics and operators. It links our own modern-day approach to the amazing long-term traditions of mechanical know-how," says Bertolini.

Bringing this customer-centric work in-house enables Rama to deliver enhanced service to its customers and increase its own efficiency. "It gives us better insight into production processes, which impacts planning, inventory, production, quality control, and more," says Bertolini. "We can also react more quickly to supply chain disruptions. And we can ensure that the customized engine conforms with all regulations and with the customer’s specs in a timely way, which is more cost-effective than making last-minute corrections. In this way, we can guarantee the level of service our customers expect of us, provide more consistent engine quality, and also reduce waste!"

"[The quality control room] plays a key role for our customers, because better quality control means higher-quality engines that have a longer life." Andrea Bertolini, operation manager at Rama Motori

The new assembly area: designed for engine quality assurance

The new assembly line is located in Rama’s production department. The 450-square-meter area has five lifting platforms and five workbenches, including one dedicated to prototypes. Three hoists (1,000- and 2,000-kg capacity) make lifting marine and industrial engines on and off the workbenches safe, quick, and easy for the staff.

Enterprise Resource Planning (ERP) software manages the production process from order to final delivery. All data is available in a centralized location with complete visibility for every functionality — order details, inventory, procurement, production, finance, sales, delivery, and more.

In the quality control room, inspection and monitoring ensure that the necessary procedures are observed at each stage of assembly and engine customization and that the engine complies with all the standards and specs defined with the customer. "This room plays a key role for our customers, because better quality control means higher-quality engines that have a longer life," says Bertolini.

A customized engine being integrated into an Energreen Alpha tool carrier.

Mindset transformation

The new assembly line has not only transformed Rama’s production department, but also reflects the distributor’s new production mindset. "This means that everyone involved must understand all aspects of the production process, including negotiating with suppliers to ensure components are delivered on time and meet our quality requirements," says Bertolini. "We have so much expertise in-house on engine technology, customization, and integration. From the top down, we are sharing it with the operators, including our three new team members, to enhance the know-how throughout the entire process."

A wealth of benefits

The assembly line began operation in February 2021. By mid-December 2021, Rama had already customized 580 engines: an average of 2.6 per day. "We expect this to increase to up to five engines per day," says Bertolini. "In all, the move to in-house assembly and customization was a major investment, but we are confident that the return on investment will be significant. We have already delivered in-house customized engines to many loyal customers, including long-term customer tool carrier specialist Energreen.

"The impact will not only be in increased production, but also the ability to more quickly satisfy our customers with high-quality customized engines that match their requirements. Happy customers are loyal customers: we want them coming back for more, while we also grow our market share with new clients."