Shop John Deere Parts

Shop.Deere.com has parts for all makes & models of John Deere equipment. Choose speedy delivery or pick-up options at your local dealer.

Search Parts Catalog

Precision Upgrades & Attachments

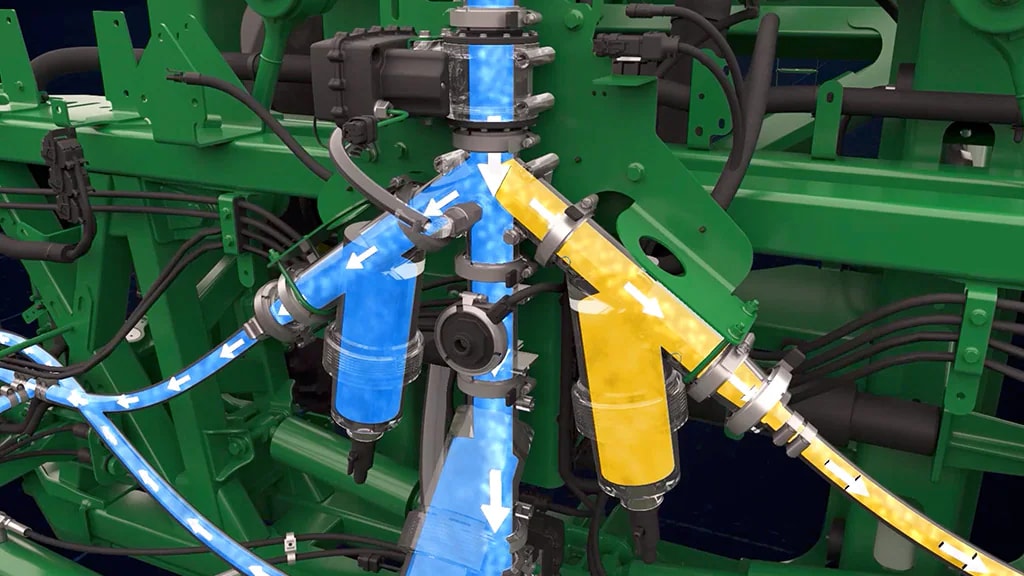

Pressure Circulation/Product Reclaim

Reduce potential crop damage with a more uniform solution at every nozzle in your application. Pressure Circulation/Product Reclaim also cuts down on your chemical and water expenses in addition to saving you time during chemical changeovers.

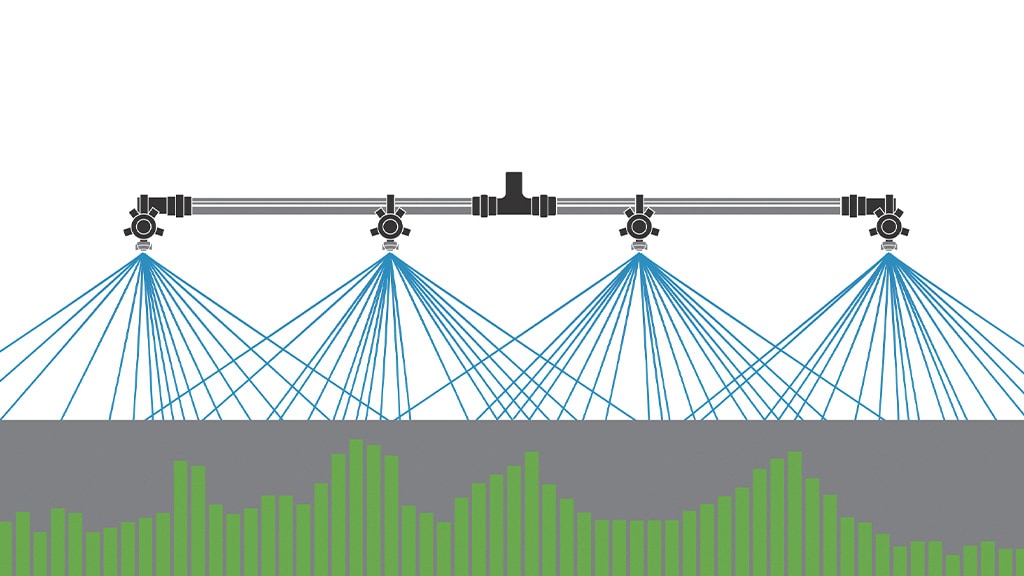

ExactApply™

Limit over-application, crop burn and off-target drift with ExactApply, which features precise droplet sizing for consistent application management at various speeds. Offering you three times the pulsing frequency of competitive systems, it also has an advanced A-B nozzle design.

Express Boom

Replace warped poly booms with durable stainless steel and change nozzle spacing as desired to maximize your sprayer performance for years to come. Customize whole boom sections easily and economically on select sprayer models.

Wheel Shields

Designed to help you prevent damage to bush-like crops, polyethylene wheel shields gently part crops so wheels and housings can easily flow past. Flexible skirt conversion kit also available to resist rocks and bumps.

Nozzles, Guide & App

Worn Nozzles

Spray nozzles are some of the smallest and most overlooked pieces of equipment on your sprayer despite having the greatest effect on accuracy, efficiency and drift potential. Learn why worn spray nozzles cause increased application rates and/or change distribution patterns that lead to under- and over-application affecting your bottom line.

Nozzle Selection

Choosing the right sprayer nozzle for your application is important to your overall success in the field. Use our comprehensive selection guide to figure out the best nozzle type to meet your needs.

Sprayer Parts Guide

Get a thorough sprayer parts overview by paging through our comprehensive guide. Read about new products, upgrades, accessories, nozzle selection, maintenance and technical information.

Maintenance & Pump

Solution System Maintenance

Regular maintenance of your solution system will help provide the best quality application, prevent contamination, and increase the life of components. Watch the video to learn best practices for cleaning out solution system parts like flowmeters, strainers, nozzles, nozzle bodies and end caps.

Erase™ Spray System Cleaner

Erase is a powerful spray system cleaner that exceeds the capabilities of ordinary tank cleaners by emulsifying oily residues in the sprayer lines/hoses. At the same time, it elevates rinsate pH to degrade vulnerable crop protection products. Includes anti-corrosion inhibitors for your sprayer pumps, seals and plumbing.

John Deere Sprayer Winterizer Fluid

Our cold weather protection fluid is the only product available specifically formulated to protect the entire wet system of your sprayer. Watch the video to see how you mitigate the risks of frozen/broken pipes, pumps, and valves with proper winterization.

ForceField™ Wet-Seal Pump

Upgrade the high-flow pump on your 4 Series sprayer with a ForceField pump, which uses wet-seal technology for added protection in harsh application environments. Even in run-dry situations, it maximizes performance and prevents chemical bonding by cooling and lubricating the mechanical seal with barrier fluid.