A New Era in Power

John Deere believes the future of power is not defined by a single solution but by a range of options that allow our customers to choose the best fit for their operations.

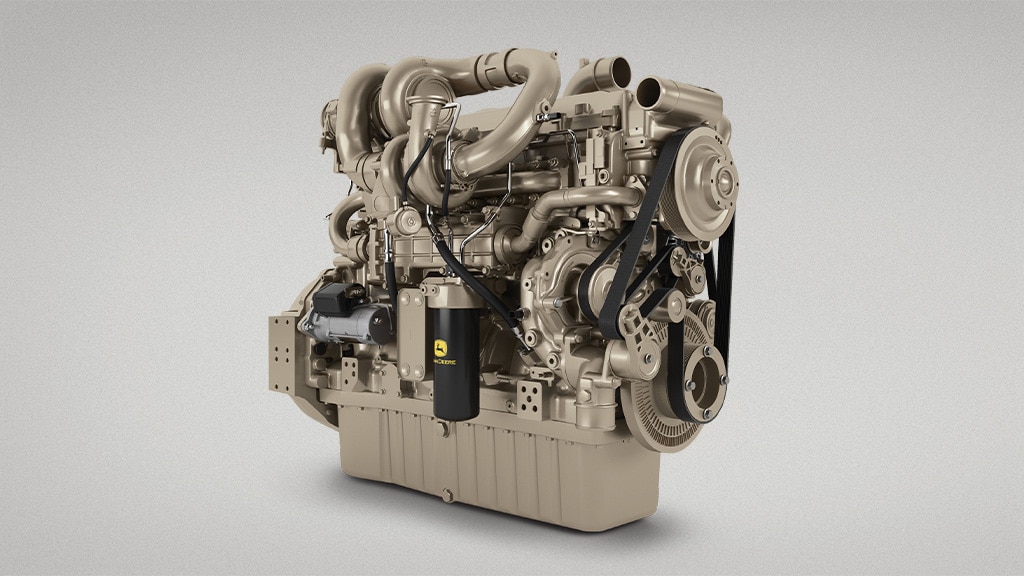

Advanced Engines

The latest John Deere engines offer the most advanced engine technologies to deliver new levels of reliability, durability, flexibility, and serviceability.

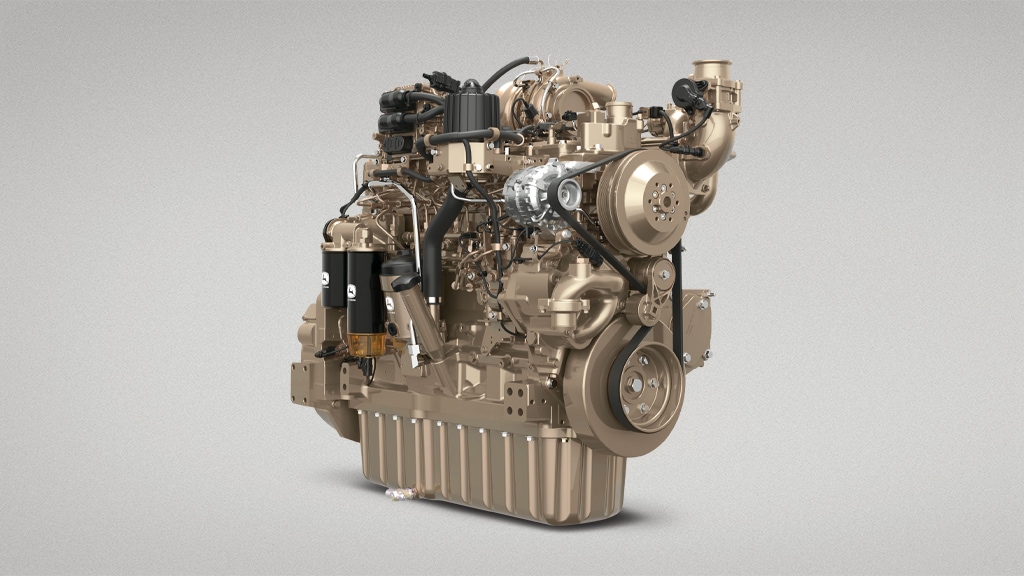

JD4G – Compact Power

Reduced Package Size

The JD4 features a 20 to 25 percent reduction in package size and a more than 50 kg (110 lb) reduction in weight compared to the John Deere 4.5L single turbo engine.

JD14 – Proven and Ready

Quiet Operation

The JD14 features a rear gear train that reduces noise by up to 3 decibels compared to the 13.5L engine. That's half as loud, greatly improving operator comfort.

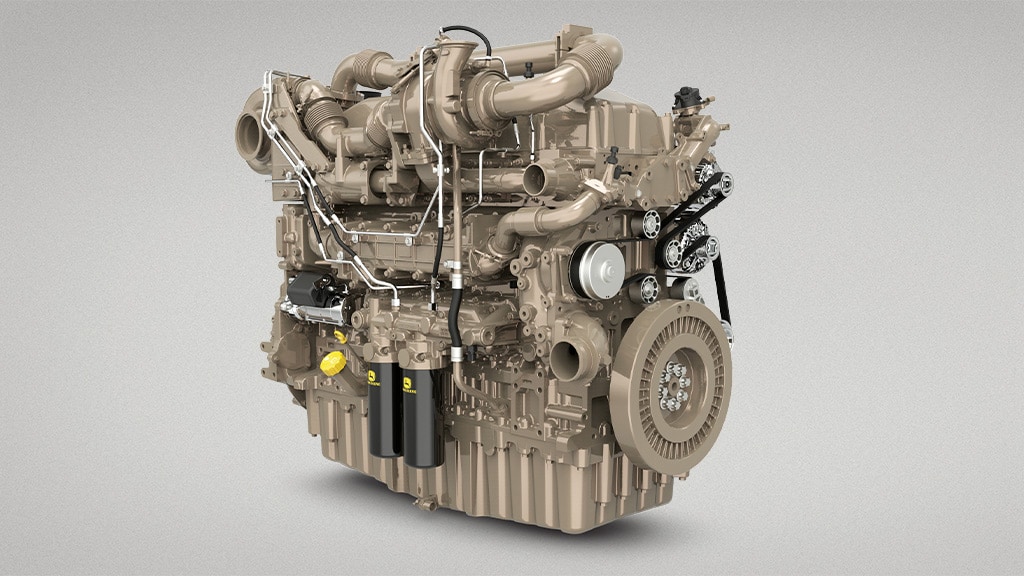

JD18 – Expanded Power

No DEF Fluid

The JD18 features new combustion technology which allows John Deere to offer an engine in the 522 – 677 kW (700 – 908 hp) power range without aftertreatment.

JD9 – Powerful Integration

Simplified Aftertreatment

The JD9 features expanded power up to 343 kW (460 hp), single- and dual-turbo configurations, and an in-line aftertreatment system for ease of application integration.

Keep It Running

Keep your OEM equipment in top operating condition with John Deere Connected Support™, extended warranties, engine maintenance plans, and reliable parts.