POWER CONNECT

Explore the latest ways people are integrating John Deere power solutions.

Stay Informed

INDUSTRIAL

Bigger Power For The Big Stick

Bambauer Equipment is offering greater flexibility for manure pumping needs with The Big Stick, now available with both JD14 and JD18 engine options.

INDUSTRIAL

Powering Precision in Potato Harvesting

John Deere and Spudnik are bringing efficiency to the potato field by leveraging electrification and power offboarding capabilities to optimize the harvesting process and crop quality.

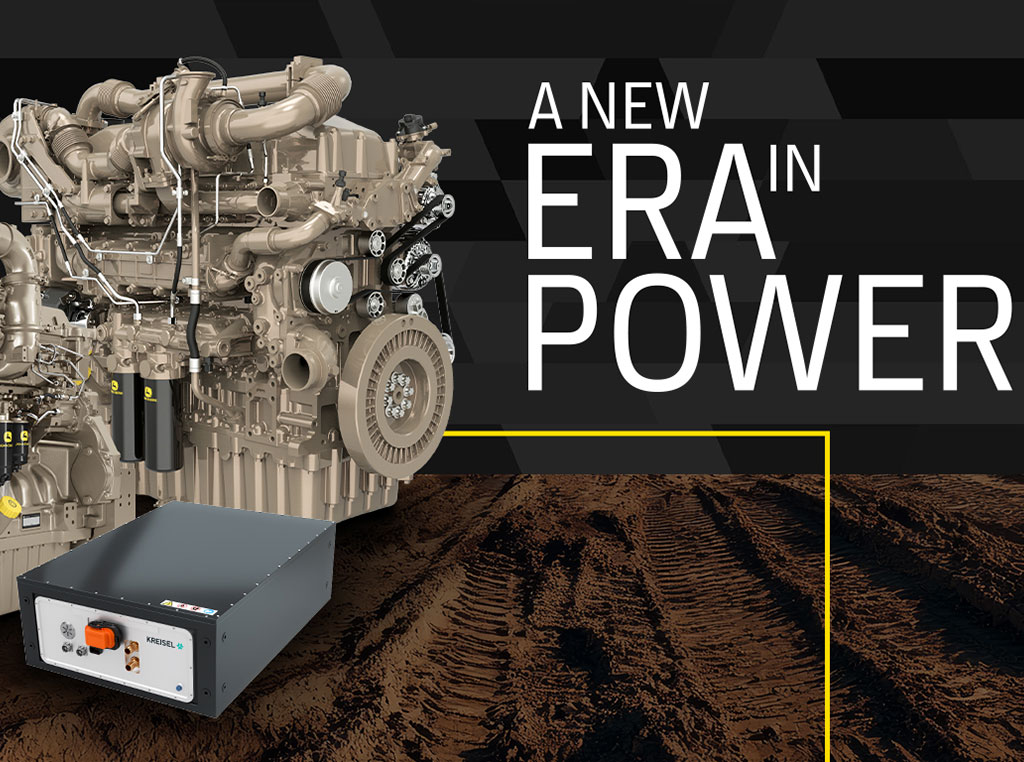

INDUSTRIAL MOBILE

A New Era in Power for Off-Highway Equipment

John Deere Power Systems leads the off-highway power evolution. Discover our advancements in industrial and marine diesel engines, cutting-edge battery technology, and comprehensive aftermarket support.

MARINE COMMERCIAL

Venice: Where Maritime Muscle Meets Romance

Learn how repowering with John Deere marine engines helped Venice's skilled pilots navigate the challenges of their unique maritime environment.

INDUSTRIAL MOBILE

Boost Hay Grinding Efficiency With JD18 Power

Discover how the John Deere JD18 industrial engine has transformed Jones Manufacturing Company's Mighty Giant hay grinder.

EMERGING TECHNOLOGIES

Support at Every Stage

John Deere Lifecycle Service Solution is a comprehensive strategy designed to maximize the performance and longevity of OEM engines. Get the full details.

EMERGING TECHNOLOGIES

A Journey of Connection and Innovation

Discover how John Deere brought cutting-edge engine tech to OEMs with the 2024 European Road Show, highlighting innovation and unmatched customer support.

MARINE RECREATIONAL ENGINES

Reviving History: Repowering the Western Flyer

Discover how a John Deere marine propulsion engine paired with a hybrid-electric system breathed new life into the iconic Western Flyer vessel.

INDUSTRIAL

Harnessing the Power of Connectivity

See how John Deere Connected Support™ is transforming Rubble Master's approach to equipment maintenance and uptime.

INDUSTRIAL

Breaking New Ground

See why Pezzolato chose John Deere’s JD14 industrial engine to power its drum wood chipper, delivering more power, efficiency, and reduced maintenance.

INDUSTRIAL

Powering Sustainable Agriculture

Chayé Hnos. helps Argentinian farmers boost water efficiency and crop production with John Deere-powered generator sets for sustainable irrigation.

MARINE COMMERCIAL

Heavy-Duty Deck Winches

A heavy-duty deck winch manufacturer turned to a John Deere engine to meet the demanding requirements of marine infrastructure work.