All-In-One: The PD400 Dual Inverter

Maximize space savings, design flexibility in hybrid electric vehicles with new PD400 modular inverter from John Deere Electronics (JDE)

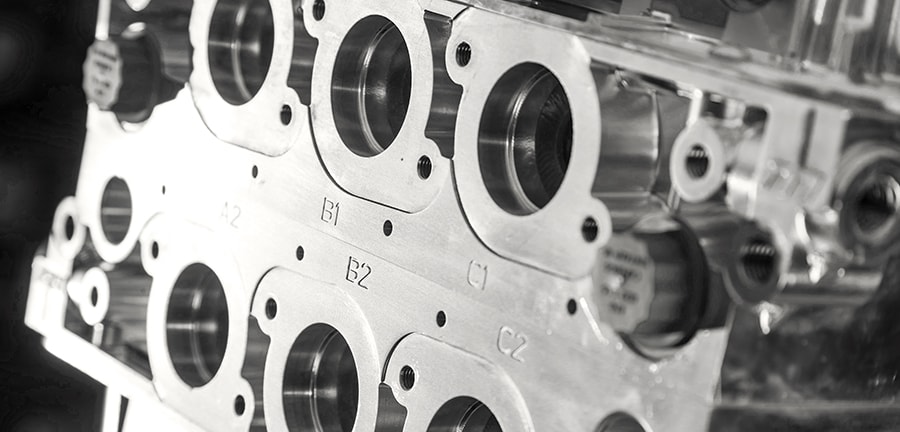

Compact and efficient machines are critical to heavy-industry customers’ success. With the numerous complex systems and their many parts, it is no surprise that utilizing space efficiently can be a challenge for engineers. The PD400 modular inverter from JDE provides space savings and flexibility to system designers with a solution for high-voltage/high-power hybrid electric vehicles. The PD400 all-in-one system eliminates the need for multiple interfaces, while also matching exact system requirements. This allows system designers to optimize design integration and machine performance in the often-extreme conditions of off-highway and heavy-duty applications.

One of the many considerations when designing a hybrid electric system is whether the system will need more than one inverter. In most modern hybrid systems, using at least two inverters is increasingly common. One often controls the ground drive functions and the others supply power to various systems, such as HVAC, electronics and energy regeneration. The PD400 modular design can be configured with a single or dual inverter for maximum design flexibility. An optional brake chopper can be used to redirect excess energy into various forms of energy storage such as batteries or ultra-caps. A problem that can arise with the use of multiple inverters is the potential for resonance, which could damage hardware or provide unpredictable power output. By using a dual inverter, the PD400 protects both itself and the machine’s other systems from resonance at a low cost while freeing up space with its compact design.

Another benefit of the compact design is its impact on energy loss and heat control. One by-product of inverter operation is the generation of heat resulting in loss of energy through the conductors and connection points. This problem only increases in severity as multiple inverters are integrated into an electrical system. Not only does the loss of energy impact the efficiency of the machine, the additional heat can adversely impact hydraulics and electronics. Cooling these systems in turn requires much more energy and thus is wasteful. The PD400 all-in-one solution, however, eliminates multiple connector and cooling interfaces to decrease cost, minimizes space requirements to allow for more design flexibility and reduces energy losses for improved efficiency.

Additional features also include an optional DC-DC converter as a potential alternator replacement and an available integrated isolation-monitoring feature for preventive maintenance use.

Because the inverter’s performance relies not only on the quality of its features but also on its proper implementation in a machine, the PD400 is engineered with system integration in mind. To facilitate easy system design, the PD400 has a common electronic control architecture that supports the full suite of JDE advanced motor control software. This optimizes performance of both permanent magnet and induction motors (common in hybrid electric applications) by ensuring accurately synchronized and mistake-proof integration. PD400 software is designed to work at maximum efficiency with complete monitoring capabilities. This provides the unique ability to precisely manipulate the controls under various operating conditions and fine-tune operating parameters during integration. The PD400 ensures quick and easy assembly for manufacturers and simple modification by application engineers. It is liquid-cooled in order to minimize the effect that excess heat from the inverter may have on the system, and for robust and reliable performance over the life of the system.

The PD400 modular inverter is the latest addition to the JDE inverter lineup — which includes the PD300. This lineup is suited for a variety of off-highway and heavy-duty vehicle applications, such as waste management, agriculture and drilling. Working in a wide range of application settings gives JDE engineers a vast amount of experience to draw on when collaborating with original equipment manufacturers on machines, as well as a confidence in the product’s quality. By developing these reliable and adaptable technologies, JDE increases end customers’ productivity and uptime. For more information, visit John Deere Electronics at www.JohnDeere.com/JDES. Or email us at ElectronicSolutions@JohnDeere.com.

About John Deere Electronics

John Deere Electronics (JDE) strives to further John Deere's global business by developing rugged and reliable electronic components and systems that thrive in the most extreme environments. To enhance innovation, expertise and competitiveness, JDE provides custom and off-the-shelf electronics and power electronics for original equipment manufacturers worldwide.