John Deere News

Featured Stories

Discover how our customers, employees, and locations are driving innovation, making a difference, and shaping communities across the country and around the world.

Read all Featured stories

Working at Deere

Meet the people behind our mission—employees who go above and beyond through community service, military support, and everyday acts of dedication.

Read all Featured stories

News Releases

Deere & Company Mourns Passing of Board Member Sherry M. Smith

MOLINE, Illinois (July 7, 2025) — Deere & Company sadly announces the recent death of Sherry M. Smith, a distinguished member of its board of directors.

John Deere Recognized as Top Community-Minded Company for Fourth Straight Year

MOLINE, Illinois (June 4, 2025) – John Deere employees have once again set new records in volunteerism over the past year, demonstrating an unwavering commitment to community giving.

John Deere Acquires Sentera

MOLINE, Illinois (May 23, 2025) — John Deere announced today the acquisition of Sentera, a leading provider of remote imagery solutions for agriculture headquartered in St. Paul, Minnesota.

Deere Reports Second Quarter Net Income of $1.804 Billion

MOLINE, Illinois (May 15, 2025) — Deere & Company reported net income of $1.804 billion for the second quarter ended April 27, 2025, or $6.64 per share, compared with net income of $2.370 billion, or $8.53 per share, for the quarter ended April 28, 2024.

Our Commitments

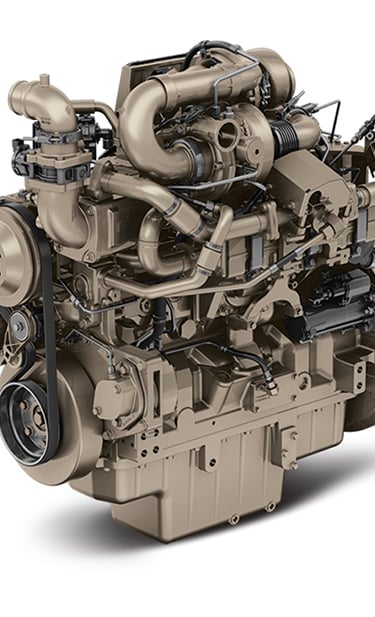

Industry News

Explore John Deere news and stories by industry.

Our Achievements

These awards highlight the exceptional support our team provides to customers and communities.

- 28 years recognized by Fortune as World’s Most Admired Companies

- 18 years recognized as Ethisphere World’s Most Ethical Companies

- 7 time award winner at the Consumer Electronics Show (CES) including (3) “Best of Innovation” awards in Robotics

- 3 years recognized by Points of Light: The Civic 50

- 2 years recognized as TIME World’s Best Companies

- Recognized as a LinkedIn Top U.S. Company