The Power Behind Material Handling

For operations that handle massive volumes of material, especially in the demanding agricultural and aggregate industries, smooth, continuous operation is the benchmark for success. In the face of dust, extreme temperatures, and relentless schedules, achieving that steady operation depends on reliable equipment.

Gruber Manufacturing, based in Northern California, is led by Mark and Todd Gruber. They manufacture mobile transload conveyor solutions for demanding industries. A deep commitment to reliability is engineered into every self-propelled material elevator conveyor they produce.

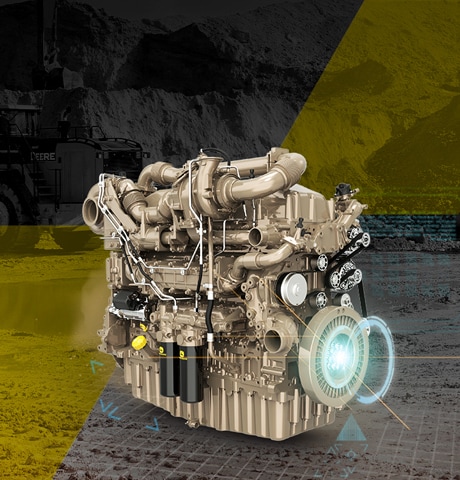

Gruber Manufacturing machines are designed for challenging applications: efficiently moving a wide range of materials, from agricultural products like almonds to vital construction aggregates. To drive these essential operations, Gruber Manufacturing relies on John Deere power.

A Foundation of Durability and Support

In sourcing the engines for its robust material conveyors, Gruber Manufacturing has long relied on its partnership with John Deere engine distributor Western Power Products. For Gruber Manufacturing, the decision to use John Deere engines comes down to two key advantages: their proven durability and the extensive global service network.

"We chose John Deere because its proven track record of building well-built, long-lasting engines instills a great deal of trust," says Mark Gruber, president of Gruber Manufacturing. "That trust extends to its support network; knowing there are service centers all across the country provides real peace of mind for our customers."

The specific workhorses Gruber Manufacturing turned to are the John Deere 4045TI530, a compact 55 kW (74 hp) 4.5L engine; and the 4045HFC04, delivering 86 kW (115 hp) from the same 4.5L displacement. The engine choice, Mark explains, often hinges on the scale of a customer's operation.

"It's all about matching the machine to the operational demand. For example, a customer processing a handful of rail cars per week prioritizes efficiency and simplicity; for them, a smaller-displacement engine that avoids the need for a DEF system is the ideal solution," says Mark. "For high-throughput operations, the focus is on capacity. They need to move massive volumes, and for them, integrating a DEF system is a standard part of running a high-performance machine."

The flexibility to provide a solution for any operational scale is made possible by the diverse John Deere engine portfolio and the expert packaging and support provided by Western Power Products.

A Turnkey Solution

In initial designs, the Gruber Manufacturing team managed the complex task of building its power units—sourcing bare engines and then engineering the integration of radiators, air cleaners, and custom-fabricated mounts.

The team at Western Power Products saw an opportunity to optimize the resource-intensive process. The engine distributor proposed an innovative, turnkey approach designed to accelerate Gruber Manufacturing's production timeline and enhance overall efficiency.

This suggestion led to the development of a fully integrated, skid-mounted power unit. Western Power Products engineered a complete, low-profile power package. The power package was pre-tested and configured to integrate seamlessly into Gruber Manufacturing's conveyor design. The new power unit immediately transformed Gruber Manufacturing's production line.

"That provides a significant advantage for our manufacturing process," says Todd Gruber, general manager at Gruber Manufacturing. "The engine arrives ready to install. We connect the battery cables and fuel lines, secure the unit, and the installation is complete. It has made the manufacturing process exceptionally efficient."

Western Power Products attributes the success of the solution to its close collaboration with the Gruber Manufacturing team.

"Mark and Todd are excellent partners because they are very specific about their operational needs," says Rich Carroll, territory sales manager at Western Power Products. “We developed a customized, turnkey power unit that functions as a true 'plug and play' solution for their assembly line."

Adding to this efficiency is the assurance of pre-delivery validation: Western Power Products meticulously tests each unit before it ships.

"When the unit arrives, it's already been fueled and tested," says Mark. "We turn the key and it starts without fail. That level of reliability is a major benefit of working with Western Power."

Field-Proven Reliability in Demanding Climates

Gruber Manufacturing also appreciated how the engines perform in extreme heat and extreme cold. Its conveyors are subject to a wide operational range, from the heat and dust of California's almond harvest to the cold, snowy winters of Canada. Even in these conditions, engine reliability is a constant.

"Our customers run these machines hard; their profitability depends on throughput, so they push these conveyors to their limits," says Mark. "The feedback is notable for its lack of complaints. When you consider they're operating in extreme heat and dust, that lack of complaints speaks volumes. To me, this confirms the engines are dependable and, more likely, that our customers' operations are staying online."

Collaborating for Manufacturing Efficiency and Field Reliability

Ultimately, the success of this collaboration is measured on the jobsite. The engineering and integration expertise of Western Power Products, which transformed a proven John Deere engine into a seamless power package, directly enables the strong performance of Gruber Manufacturing's conveyors.