Agriculture, Livestock/Poultry January 01, 2026

Broiler Breeder

Supplying broiler chicks gives Ontario producer a great opportunity.

Story and Photos by Lorne McClinton

How do you grow and diversify a cash-cropping and custom-farming business in Southern Ontario, where competition makes good land expensive and scarce? Peter and Martine Rastorfer of Monkton, Ontario, have tried different approaches but their real breakthrough came in 2019 when they picked up broiler breeder egg quota. They've finally found the right mixture of diversity and stability they were looking for.

Broiler breeder farmers don't produce eggs for the general public, they work on a business to business (B2B) model. The Rastorfers' operation produces fertilized Ross 708 broiler eggs for the Maple Leaf Foods hatchery in New Hamburg, Ont., on an 11-month cycle. The hatchery in turn supplies day-old chicks to broiler barns across Ontario. It's not a big industry; there are only about 78 broiler breeder operations in all of Ontario.

The Rastorfers initially received 10,000 HEMs of quota. This allows them to ship about 2.1 million fertilized eggs to the hatchery over their 11-month cycle.

Rastorfers' cycle begins with 14,000 20-week-old pullets (young hens) arriving at their barn from a contract pullet grower. Hens and roosters (10% are roosters) mingle freely inside the highly-automated barn that dispenses food and water to the flock at carefully monitored rates. They start laying small fertilized eggs in nests at 24 weeks, but eggs don't reach shipping size until 26 weeks. An automated collection system brings them to the sorting station.

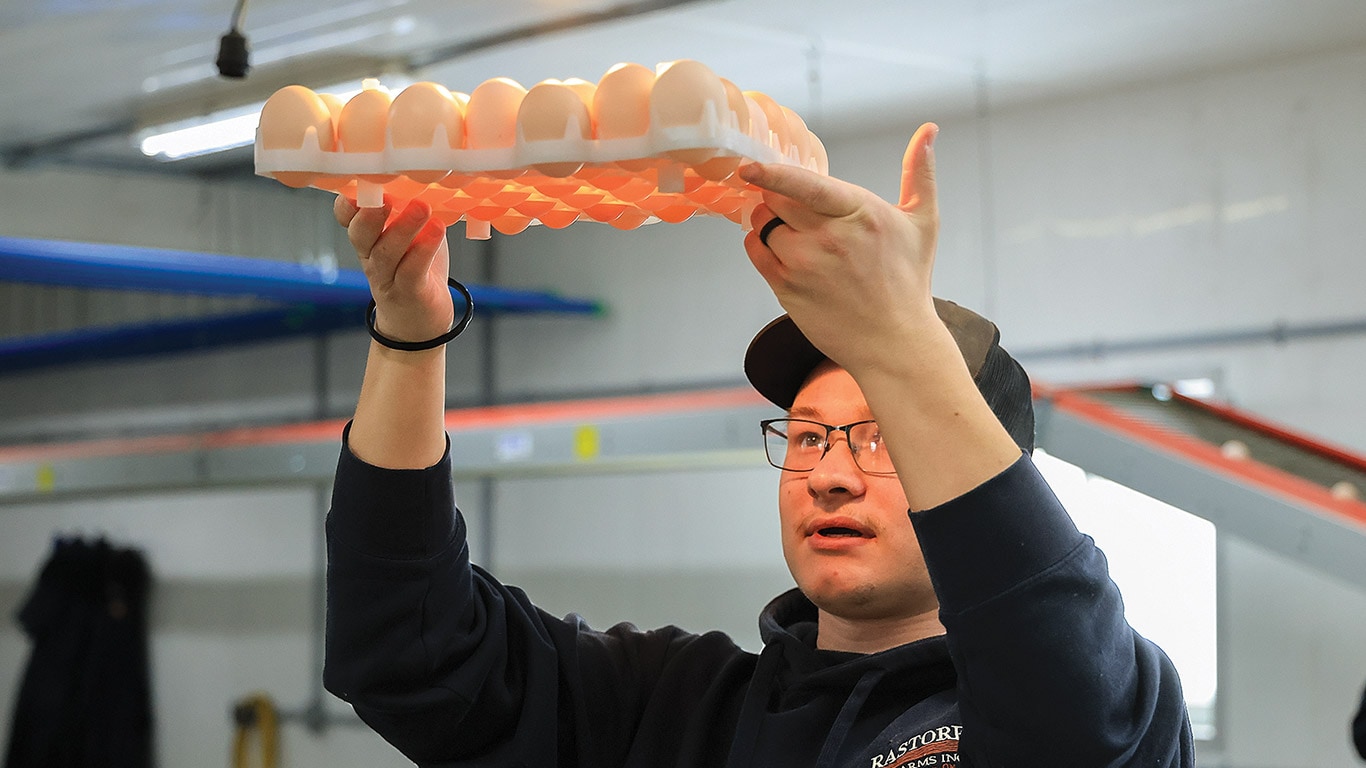

Eggs are carefully checked and candled to assure they're fertilized and then packed 5,000 eggs per cart before they're stored in a cooler. These are then picked up twice weekly by Maple Leaf.

Despite the high degree of automation in the barn, human eyes are still an essential part of the equation. Broiler chicken varieties have been specially bred to be fast-growing birds. Most of the ones people buy in supermarkets are barely two months old. This makes it challenging to raise them to produce eggs.

"Every week we weigh birds, tweak their feed, adjust lighting," Rastorfer explains. "Too heavy, they won't lay. Too light, they won't thrive. It's a balancing act."

Broiler breeder producers raise their birds under Canada's supply management quota system which carefully regulates the number of eggs so the supply closely matches demand. Quota isn't readily available. So, when the Rastorfers had the rare chance to obtain quota without having to buy an existing facility, they jumped at it. This not only gave them the opportunity to build a new state of-the-art barn, but they kept both their cash crop and broiler breeder operations at their existing farm site.

Above. Despite the high level of automation in the Rastorfers' broiler breeder operation, human eyes remain an essential part of the equation. Every week birds are weighed and their feed is tweaked based on the results.

Life's uncertainties. The original business plan had Martine managing the broiler breeders and Peter focusing on cash cropping. That all changed abruptly when she suffered a major stroke in 2022. Peter now runs the broiler breeder side too with the help of a hired man.

The operation is growing, the Rastorfers are adding a twin barn across from their existing one, that will come onstream in February 2026. Their quota will rise to 17,500 HEMs allowing them to ship 4 million fertilized eggs per cycle. The second barn also allows them to stagger their production cycles to keep the eggs flowing year-round.

Peter has no plans for additional expansions in the future. The farm now has the capacity to bring the next generation into the operation if they choose. But there is no pressure to do so. However, with their oldest son currently studying agriculture at Olds College in Alberta, they're hopeful one might.

Chicken consumption in Canada remains strong but the growth rate has cooled. Global politics and trade deals have added a new degree of uncertainty. For now though, the Rastorfers still see resilience in the sector.

"We've got water, we've got decent summers, and we've got supply management," Peter says. "That gives me confidence." ‡

Read More

AGRICULTURE, EDUCATION

Shoo, Flies!

Effective fly control is a quick way to add pounds to beef.

AGRICULTURE, SPECIALTY/EDUCATION

Teaching Through Tomatoes

4-H members learn to grow and give.