Agriculture, Education June 01, 2025

Cotton Gin Clean Slate

Tornado forces choice of rebuild or relinquish.

by Martha Mintz

It took but a few short minutes for a tornado to reduce the Milstead Farm Group cotton gin to a tangle of steel. The only thing equal to the force of the storm was the will of the employees, board, and farmers intent on rebuilding a faster, more efficient version of the crucial infrastructure.

The tornado struck the Shorter, Alabama, facility at 2:57 a.m. March 27, 2023—just weeks before area farmers were set to plant their cotton crops. A spotlight beam cutting through the early-morning dark revealed worst-case scenario when Milstead Farm Group president Shep Morris and manager Joey Scarborough finally navigated their way past downed electric lines and other obstacles to reach the gin.

"It was a mangled mess. It took my breath away," Morris says. Even the concrete footings were destroyed where columns fell.

"Within minutes, Shep was talking about how we had to rebuild. I thought, 'No way. He's thinking emotionally,'" Scarborough says. Emotional or not, Morris was determined and soon had everyone else on board, too.

By 5 p.m., just 14 hours after the tornado, the executive board voted to rebuild when they could have taken the insurance check and simply walked away.

"People doubted us, but failure wasn't an option," Morris says.

Built in 1998 by Morris and a group of other area farmers, the gin was the largest left serving their central Alabama community. It ginned more cotton than the few remaining small gins in the region combined, Morris says.

"If we were going to keep growing cotton, we needed the capacity. I don't think the rest of the gins could have made up the difference without us," he says.

They had roughly seven months to completely rebuild before cotton modules started flowing in from thousands of acres.

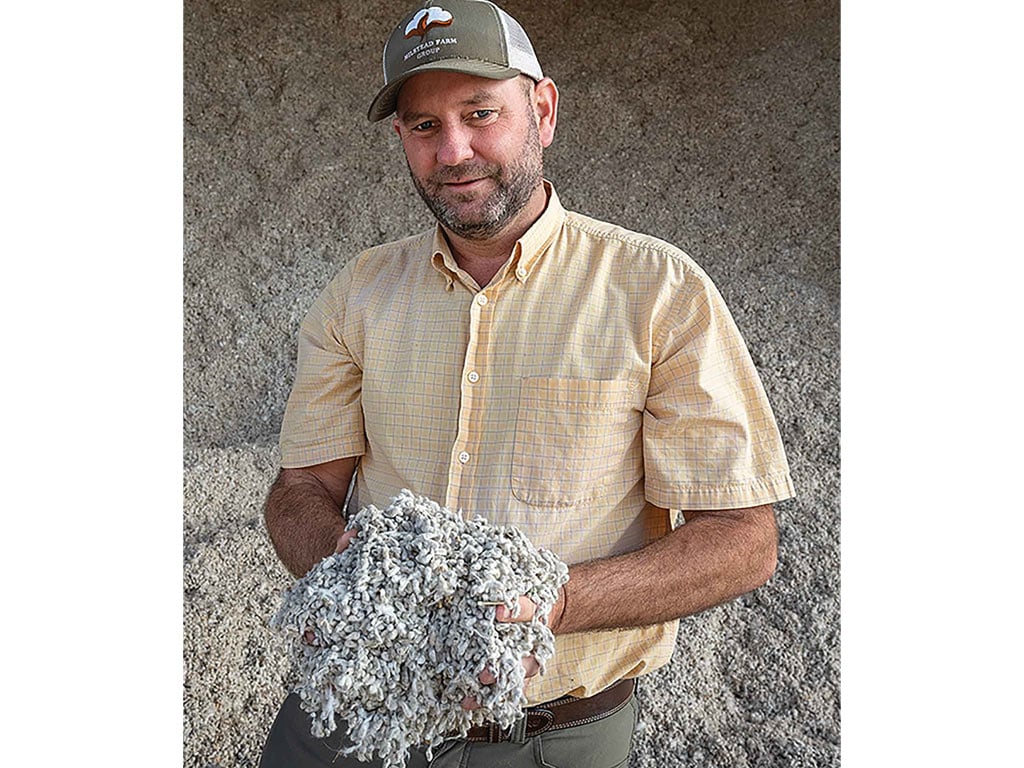

Above. Milstead Farm Group gin manager, Joey Scarborough was one of the first to see the destruction that led to a frenzied 6-month rebuild.

Conducting chaos. Calls started going out immediately. Nearly every component needed replaced short of the gin stands themselves, which were left standing cradled in the mangled ruins. At the time, getting something as simple as an oil filter was a trial, Morris says. Within a few days, it was confirmed they could get key components quickly, including critical pieces that needed to be manufactured in India.

"Our contact said they would stop the line in India and make us what we needed. The whole project was a function of relationships," Morris says. From the insurance company to the electricians, everyone came together to make it happen.

Visualizing the project's many moving parts was difficult early in the process and took its toll on confidence. One day, Morris sketched out the new production line on a whiteboard, color-coding each piece by the company providing the materials. Blue for India, red for Florence, Alabama, green for Lubbock, Texas, purple for Salem, Alabama, and so on.

The sketch lives on in the office as a reminder of the collaboration at the heart of the project's eventual success.

It took two months to clear the rubble, four months to rebuild and get the gin up and running. On October 19, the first bale emerged from the press. There was little pomp and circumstance as there was work to be done in the field and the gin, but they made their deadline as promised.

The frenzied months didn't just get the gin back online. A clean slate allowed for Milstead Farm Mill to be built back better.

They seized the chance to add technology, remedy choke points, automate, and maximize efficiency.

Larger cleaners, wider feeders and dispersers, more efficient burners and dryers that use sensors to quickly ramp up and down to manage moisture, and more have all led to more consistent, efficient production.

Prior to the storm, the mill would average 700-800 bales of cotton produced per day and hit 1,000 bales on a good day. Now the mill can consistently turn out 1,000 bales per day. Benefits go beyond a faster turnaround for farmers.

"We increased capacity and reduced the cost of power and labor per bale produced, which helps everybody," Morris says.

Customers get larger rebates, the mill is more profitable, and the future for cotton in the area is a little more certain for all involved.

"Costs are increasing and that's forcing consolidation of gins to speed up, too. We're now set up to go further and gin more cotton without major remodels," Scarborough says. ‡

Read More

AGRICULTURE, FARM OPERATION

A Sweet Legacy

Another generation of Hirakatas are primed to produce.