HarvestLab 3000 enables operators to make high quality forage

HarvestLab 3000 measures dry matter and constituents on the go

HarvestLab 3000 measures dry matter and constituents on the go

The HarvestLab 3000 sensor mounts to the top of the discharge spout and takes accurate dry matter and ingredient readings (more than 4000 measurements per second) of the crop through the sapphire glass lens as crop passes through the spout. This is the same technology forage labs use to measure dry matter.

HarvestLab 3000 with John Deere Constituent Sensing measures dry matter and constituents like sugar, starch, acid detergent fiber (ADF), neutral detergent fiber (NDF), crude fiber, crude ash, crude protein, and crude fat depending on the crop. In addition, the HarvestLab 3000 sensor can also be used as a stationary unit.

Stationary Unit for HarvestLab

Stationary Unit for HarvestLab

Crop type and constituent sensing

Crop type |

Moisture / dry matter |

Crude protein |

Crude starch |

NDF |

ADF |

Crude sugar |

Crude ash |

Corn |

X |

X |

X |

X |

X |

--- |

--- |

Alfalfa |

X |

X |

--- |

X |

X |

X |

X |

Whole crop silage |

X |

X |

X |

X |

X |

X |

X |

Grass |

X |

X |

--- |

X |

X |

X |

X |

When HarvestLab 3000 is used in conjunction with JDLink and the JD Operations center, a wealth of important information becomes available to the operator, including productivity in acres per hour, throughput in tons per hour, total area harvested, total crop mass harvested, yields, and dry matter. All data documented on the G5Plus Universal Display is shown in John Deere Operations Center.

Constituent data in Operations Center

Constituent data in Operations Center

When the HarvestLab 3000 is used in conjunction with the F8 and F9 Series Self-Propelled Forage Harvester (SPFH) and a G5 display, AutoLoc functionality is automatically available. AutoLoc automatically varies the length of cut according to the desired crop-dry matter correlation settings based on the dry matter readings from the HarvestLab 3000 sensor. With the AutoLoc adjustment, bunk density is improved and a high forage quality is reached.

Guidance options on F8/F9 SPFH

AutoTrac

Make long days easier with equipment and technology that works together for you. As equipment gets larger and margins tighter, accuracy of in-field operations and input placement is more critical than ever.

When making a pass in a field, traveling from one end of the field to another, the position accuracy of the return pass is critical. Pass-to-pass accuracy means the planter guess rows will be accurate and subsequent passes are less likely to result in crop damage.

AutoTrac™ assisted steering system greatly increases operator productivity by maintaining consistent accuracy and efficiency. Operators remain more alert while they are in the field and are able to focus on forage harvester settings and varying field conditions. AutoTrac also allows operators to confidently create evenly spaced rows past sunset, as well as in rain, dust, or fog.

AutoTrac provides the following benefits:

- Reduced overlap and soil compaction

- Greater field working speeds

- Reduced fuel and input costs

- Controlled traffic systems functionality

- Significantly reduced operator fatigue

To run AutoTrac, an activation is required on the display.

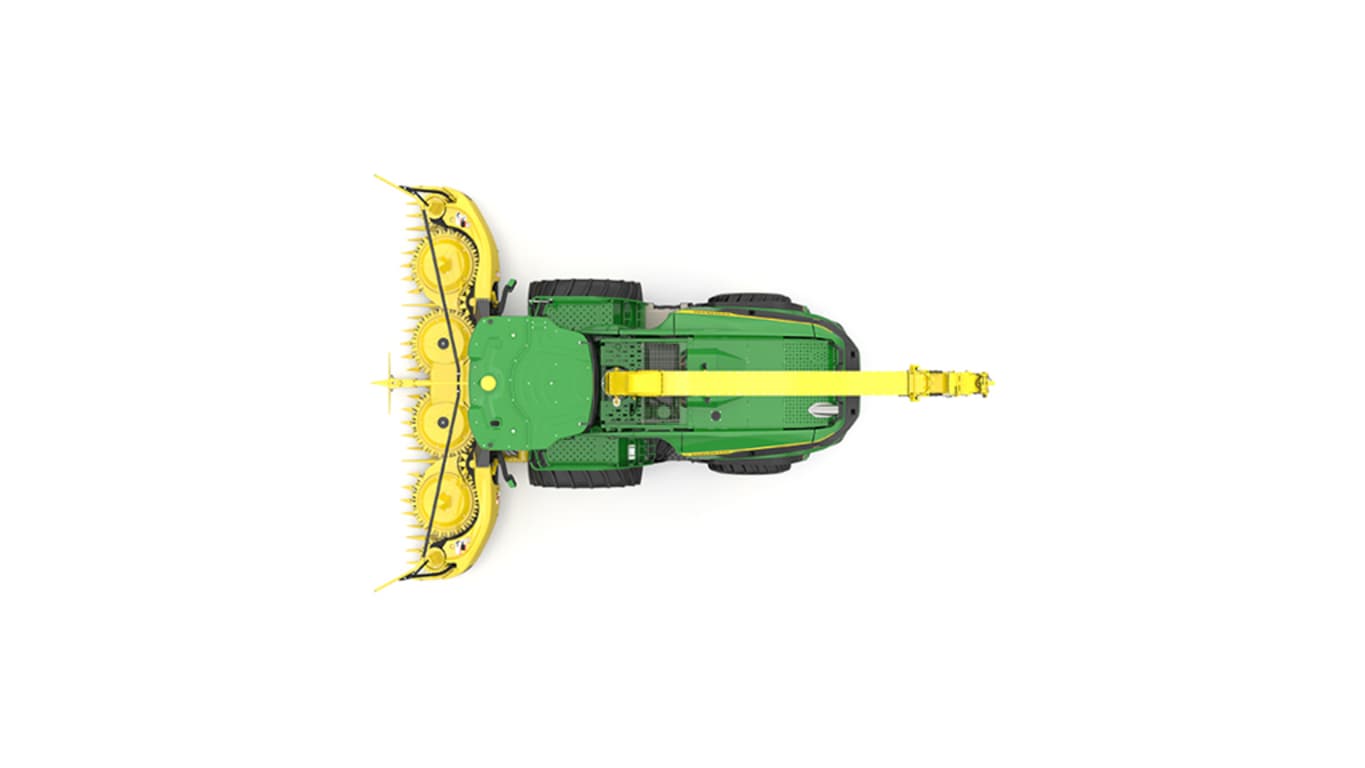

AutoTrac RowSense

AutoTrac RowSense is the next step for higher efficiency in corn harvest. This industry-leading technology fuses together satellite position data from the StarFire™ Receiver with feeler data gathered from the row sensor, allowing the operator to reach greater levels of productivity. AutoTrac RowSense in combination with an RTK signal allows the operator to benefit from repeatable accuracy of up to +/- 2.5 cm (1 in.) pass after pass. Operators can experience all the benefits of AutoTrac, including pinpoint accuracy, with AutoTrac RowSense as it enables automatic guidance in corn harvest. The technology allows the corn head and harvester to stay between the corn rows, keeping AutoTrac engaged and the operator relaxed.

To use AutoTrac RowSense, the header needs to be ordered with row feelers. An AutoTrac activation is needed as well.

Automation options for F8/F9 SPFH

Active Fill Control (AFC)

AFC automates the filling process

AFC automates the filling process

Improve the forage harvesting experience through automatic spout aiming from Active Fill Control (AFC). This advanced system uses a camera to detect the forage truck or trailer and the amount of forage in the truck. AFC then controls the spout rotation and flap position to execute an operator-selected fill strategy to the optimum fill level. The fill progress can be monitored in a quick glance by watching the video stream on the G5 or G5Plus Display. Once the trailer is full and pulls away, AFC automatically begins searching for the next trailer without any need for the operator to adjust the spout. After headland turns, the spout automatically returns to the last filling position unless the operator is using ProTouch Harvest.

Beginning in MY26, the AFC system is completely re-designed with a new stereo camera, controller, software and accuracy.

AFC improves operator comfort by alleviating the stress of continuously monitoring the filling process. The operator has the freedom to focus on other tasks like machine optimization or communication with the harvesting fleet.

When harvesting in challenging field conditions, AFC keeps the spout aimed into the truck to minimize forage loss.

Rear unloading is possible if the machine is equipped with a StarFire™ receiver.

ProTouch Harvest

In MY26, John Deere equipped the F8 and F9 forage harvesters with ProTouch Harvest. ProTouch Harvest expands on the previous ProTouch feature utilized by customers. ProTouch Harvest allows customers to start harvesting faster than ever. Preconfigured for corn, grass, and whole crop silage, ProTouch Harvest uses just one click to engage six harvester functions in an adjustable sequence. Whether headed into the field or heading home, that saves you time by reducing operator interactions.

Please refer to the ProTouch Harvest animation by clicking here.

Ground Speed Automation

To maximize productivity and efficiency of the new John Deere F8 and F9 forage harvesters, regardless of operator John Deere has introduced Ground Speed Automation (GSA). Becoming a skilled forage harvester operator is no small task, especially with the many things occurring at the same time while becoming familiar with forage harvester operation. That’s where the value of GSA is recognized by customers. Ground Speed Automation allows customers to set a max speed, a harvesting set point and the overall aggressiveness of the system.

When GSA is active, during chopping the system is designed to keep the machine at the optimal engine load. Therefore, as the machine encounters light crop the machine ground speed will increase automatically and when the heavier crop is present the ground speed will be reduced. This allows the machine to always perform at max capacity and efficiency. Owners now can put a general laborer in the seat of the SPFH and thanks to GSA that operator will soon be considered skilled labor with their operating efficiencies.

Display and Receiver Options for the F8/F9 SPFH

G5 CommandCenter™

G5 CommandCenter™

In MY26, John Deere forage harvesters feature a 10 in. (25.65 cm), 1080p HD, capacitive touchscreen. Tied with a StarFire™ Position receiver, the G5 CommandCenter™ provides the power needed to perform all of John Deere’s precision ag features. The G5 CommandCenter™ display includes the following:

- View your information with configurable run screens

- Quickly access information with shortcuts

- Straighten your rows with an optional AutoTrac License

- Reduce overlap with optional Section Control License

- Document data and send it to Operations Center for analysis with Data Sync

- Help operators out from afar with Remote Display Access

- Optional AutoTrac RowSense License when guidance accuracy is critical

- Optional Advanced Licenses to make your day easier

- 4 Analog Digital Input to improve your view of machines, and fields

- 2 Digital Video Inputs (Ethernet) for future use

- RS232 Serial Ports to document and use prescriptions on third-party controllers

- ISO VT and ISO Doc Compatibility to view and document third-party controllers

The G5 CommandCenter ships from the factory with these three features included with the display and machine purchase so that you can easily take the first steps on your precision ag journey:

- Documentation

- Data Sync

- Remote Display Access

G5 CommandCenter also has the option from the factory to add AutoTrac™ and AutoTrac RowSense™ for F8 and F9 forage harvesters. These will stay permanent with the display.

Combine the display with a StarFire™ Receiver, and you are ready to get started with automated guidance by creating maps showing work completed and, if you have JDLink™, wirelessly sending your data to the John Deere Operations Center. If you don’t need automated steering, you can deduct AutoTrac when ordering your machine. G5 displays also give you the option to improve your accuracy with AutoTrac RowSense and automating machine functions with G5 Advanced Licenses on capable machines.

G5Plus CommandCenter

The G5Plus CommandCenter is an optional display choice for John Deere forage harvesters featuring a 12.8-in. (25.65-cm), 1080p HD, capacitive touchscreen. Tied with a StarFire™ Position receiver, the G5Plus CommandCenter provides the power needed to perform all of John Deere’s precision ag features.

The G5Plus CommandCenter display includes the following:

- View your information with configurable run screens

- Quickly access information with shortcuts

- Straighten your rows with AutoTrac License

- Reduce overlap with Section Control License

- Document data and send it to Operations Center for analysis with Data Sync

- Help operators out from afar with Remote Display Access

- Optional AutoTrac RowSense License when guidance accuracy is critical

- Optional Advanced Licenses to make your day easier

- 4 Analog Video Inputs to improve you view of machines, implements and fields

- 2 Digital Video Inputs (Ethernet) improving visibility in low-light operations and during road transportation

- RS232 Serial Ports to document and use prescriptions on third-party controllers

- ISO VT and ISO Doc Compatibility to view and document third-party controllers

- Extended Monitor Capability puts more information available in one glance and more controls at your fingertips

G5Plus CommandCenter

G5Plus CommandCenter

The G5Plus CommandCenter ships from the factory with precision ag features included with the display and machine purchase, so that you can easily take the first steps on your precision ag journey:

- AutoTrac™ guidance

- Documentation

- Section Control

- Data Sync

G5 displays also give you the option to improve your accuracy with AutoTrac RowSense and automating machine functions with G5 Advanced Licenses on capable machines.

StarFire 7500 Receiver

StarFire 7500 Receiver

StarFire 7500 Receiver

When it comes to large agricultural, small agriculture and turf customers, the StarFire 7500 Receiver is precise – allowing for repeatable placement of machines, fertilizer, seed, and herbicides.

- 100 percent increase in satellite constellations used by the receiver*

- 17 percent greater accuracy*

- Long-term repeatability (where applicable) vs. 9 months*

- 73 percent reduction in pull-in time*

- Universal offering that’s compatible with older and competitive equipment

- Interchangeable: tillage, planting, spraying, and harvesting

*All comparisons made to the StarFire 6000 with SF3

Remotely monitor and increase uptime with JDLink and John Deere Connected Support

Monitor machines in the field to keep operations running

Monitor machines in the field to keep operations running

Overview

The John Deere Connected Support tools help to remotely monitor and proactively service machines to increase uptime. All forage harvesters are enabled to use the below Connected Support tools and are included in the base price. JDLink hardware and connectivity is required for Connected Support.

Benefits

- Live machine data from field

- Increase machine uptime through preventative maintenance and diagnostics

- Keep operation running with timely support

- Remote Display Access

Additional details

JDLink system

The optional JDLink telematics system from John Deere Precision Ag Technology allows operators to optimize the true performance capabilities of their self- propelled forage harvester (SPFH). Optimization occurs by continuously collecting and transmitting machine data for machine management purposes. Machine data will be transferred wirelessly to a computer and/or mobile phone. In collecting operational information, the system enables the preventive maintenance and remote diagnostics of SPFHs, as well as the tracking of machines.

Information collected by JDLink includes location, machine hours, oil temperature, idle time, maintenance intervals, and a variety of other machine settings.

The data collected by JDLink is communicated to a central John Deere server and made available to registered users via a password-secure JDLink website. Machine owners can then access valuable equipment information quickly and efficiently to optimize machine operations before problems are realized by the current operator.

All SPFHs are equipped with the JDLink hardware ex-factory. This includes an integrated cab wiring harness, 4G antenna, and Modular Telematics Gateway (4G MTG) with Service ADVISOR™ Remote capability.

The JDLink connectivity can be turned on in Operations Center. For more information, view JDLink.

NOTE: JDLink is not available in all geographic regions.

Service ADVISOR

Service ADVISOR diagnostics greatly assist in reducing service costs and downtime. It allows the John Deere service technician to readily extract vital information about machine malfunctions through the Service ADVISOR data port. Diagnostic codes and controller area network (CAN) bus statistics stored by the machine and visible in the CommandCenter™ display are used by service technicians to isolate, identify, and resolve problems.

Service ADVISOR Remote

Service ADVISOR Remote extends the machine connectivity of JDLink. With Service ADVISOR Remote, machines can be diagnosed remotely, saving the cost of a field service call. For example, diagnostic trouble codes can be reset, and software updates can be uploaded remotely.

Remote Display Access (RDA)

John Deere RDA enables quick communication around settings or messages on the displays. This allows the dealer or the farm manager to connect with the in- cab display and assist remotely with set up, performance optimization, or troubleshooting the machine. This improves the quality and efficiency of work while saving time and money.

Wireless Data Transfer (WDT)

WDT makes it easier than ever to manage prescription and field documentation files. Send and receive files seamlessly with the push of a button and eliminate the need for USB sticks and data cards. This feature allows operators the ability to share information with trusted advisors and make data-driven agronomic decisions that boost productivity and profit.