It's your machine. We just built it.

When we set out to build a revolutionary cotton harvester, we went to the experts – cotton growers from across the country.

And what we heard was that you need a fast, cost-efficient harvest. That's why we put so much in our mean, green, harvesters. Machines designed to work as hard as you do.

Features

Whether it's the comfort of its spacious cab, the legendary power from its JD engine, or the revolutionary design of its module building and handling system, every feature on your C770 harvester is designed to save you time, costs, and stress when it counts most1.

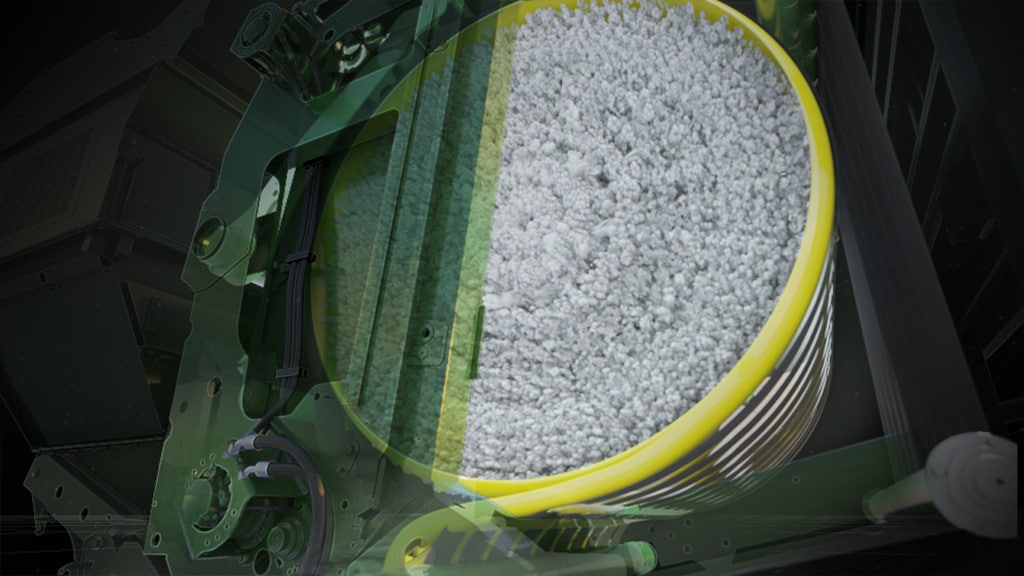

Module Building and Handling

Save up to 12% on Wrap and Hauling

To help maximize cost efficiency, we redesigned the round module builder as well as the wrapping and handling system; both the CP770 and CS770 now pack more cotton into each module, reducing the per-pound cost of module wrap and module hauling.

Improved Wrap Feeding

Experience consistent wrap feeding, module after module, with the new positive drive wrap system…operators will appreciate the reliability of the system, along with the simplicity of loading.

Denser Bales = Less Wrap Per Pound

Picker customers, the new CP770 returns a solid 8% savings in wrap and hauling costs per lint pound, compared to its predecessor; stripper growers, the CS770 gives you a 12% reduction per lint pound in wrap and hauling.

Reduced Module Wrap Time

Our next-generation module handling system cuts the module wrap-eject cycle time by 33%, from 48 seconds to 32 seconds, allowing you to stay at harvest speeds longer, and making every harvest day more productive.1

Increase Turnout With Improved Cleaning

Reduce your seed cotton losses with the high-capacity three-drum onboard field cleaner. Independently tested, results show a 10% increase in cleaning efficiency3 and removes more plant material in the field - reducing your wrapping, hauling, and ginning costs.

Engines and Hydraulic Power

Efficient, Quiet, Usable Power

At the heart of the C770 Series is the John Deere 13.6 L PowerTech™ engine, tuned to deliver the power you need, when you need it, with less fuel consumption, lower noise levels, and higher transport speed1.

Increased Fuel Efficiency

Improved fuel efficiency lets you harvest more with every gallon. The CP770 uses 20% less fuel than its predecessor, while the CS770 uses 15% less fuel than the previous stripper.

Higher Transport Speed

You and your operators will appreciate the increased transport speed…you can run from field to field at 20 mph (32.2 km/h), up from 17 mph (27.3 km/h) over previous models.

Reduced Noise

With the engine working at an easy 1,900 RPM, you'll notice reduced noise in the cab…3 dBA less in the CP770, 5 dBA less in the CS7701.

Reduced Complexity

We've redesigned the engine and hydraulic power module to use fewer unique parts, reducing complexity and improving maintenance and serviceability.

Picker Row Units

Pick Another 4.4 Acres per Day

You know better than anyone…the longer cotton stays in the field after defoliation, the more the lint quality degrades. So we gave our row units the speed you need to get out of the field faster1.

Auto Greasing System

Automated greasing gives you day-to-day confidence that bars, spindles, and gears are always properly lubricated to increase reliability.

Improved Crop Flow

Wider air doors give the new MP16 more free flow of crop to the air ducts. The result? Increased throughput and reduced plugs without increasing unit weight of fan power.4

Hydraulic Pressure Doors

This dealer installed kit allows you to hydraulically adjust torque pressure on air doors — right from the cab. When ground speed reaches 0 the door pressure drops to help clear plugs. That saves you time.

Solution System

Ever wish you could increase pressure on your solution system? Stop wishing with the new solution system. It gives you a broader operating range for your nozzle configuration, so you can improve distribution during flush. That not only gives you more even spindle solution distribution, it allows you to flush in crop to keep spindles clean during long runs.

Stripper Headers

More Acres with Less Hassle

Stripper-cotton producers…if you'd like to harvest more acres per day, we have your answer: the new SH12F Folding Stripper Header. We put major productivity and transportability into an easy-folding header, then redesigned the header attachment system for quicker, easier hookup.

12-Row Folding Header

The new SH12F 12-row Folding Stripper Header lets you cover 48% more acreage per hour than an 8-row header on our previous stripper. The SH12F folds in under a minute, and can be transported without removing it.

Three Available Headers

The SH12F joins our SH8R 8-row and SH12R 12-row rigid headers to create a complete lineup of stripper headers. The SH8R can accommodate 36-, 38-, and 40-in (91.4-, 96.5-, and 101.6-cm) rows; the SH12R can handle 30-, 32-, and 36-in (76.2-, 81.3-, and 91.4-cm) rows, while the SH12F takes on 38- and 40-inch (96.5- and 101.6-cm) rows.

Improved Header Hookup

When you do need to attach and detach the header, new no-tool hydraulic hookup cuts the time in half, to an easy-to-handle 15 minutes.

Comfort and Convenience

30% Larger Cab

From the shock-absorbing ActiveSeat™ II to the hard-driving sound system, we have the standard and available features you need to build the harvest-time office of your dreams. We'll start with a cab that not only has 30% more space than the previous harvesters, but also features familiar, automotive styling, heat-to-feet HVAC ducts, a display that swivels with the seat, and plenty of USB ports for your devices.

ActiveSeat™ II Suspension

ActiveSeat II Suspension reduces vertical seat motion by up to 90 percent, as compared to an air-suspended seat. Standard with Ultimate Cab Package.

Touchscreen Radio

Available in our Premium and Ultimate Cab Packages, the SiriusXM-ready radio lets you listen to your favorite music, podcasts, or audiobooks. Two speakers plus a subwoofer give you the ultimate audio experience.

Foot Rests

Take a load off and get comfortable with our foot rests, available in the Premium and Ultimate Cab Packages.

Refrigerator

Order our Premium or Ultimate Cab Package, and you'll get a roomy fridge, perfect for keeping lunch and drinks cold.

Technology

Cotton’s most advanced technology.

It takes data to make informed decisions. And when you harvest your cotton data with the G5Plus CommandCenter™ Display and integrated StarFire™ Receiver, you, your consultants, and your ginners can turn mapping data into actionable decisions to improve your productivity and profitability.

See More. Know More.

Do More.

Our new G5PlusCommandCenter™ display offers clear, 1080p HD resolution on a 12.8-inch touchscreen. Precision ag technology includes AutoTrac™ Documentation; Harvest Identification, Cotton Pro; Data Sync; JDLink™ Modem; over-the-air updates; and Remote Display Access all standard.

JDLink™ Connectivity

The C770 Series comes with JDLink connectivity, giving you easy communication with your machines, your operators, and your dealer. Analyze progress and performance, transfer data to and from machines, and use Machine Alerts and Service ADVISOR remote to pre-empt or diagnose issues.

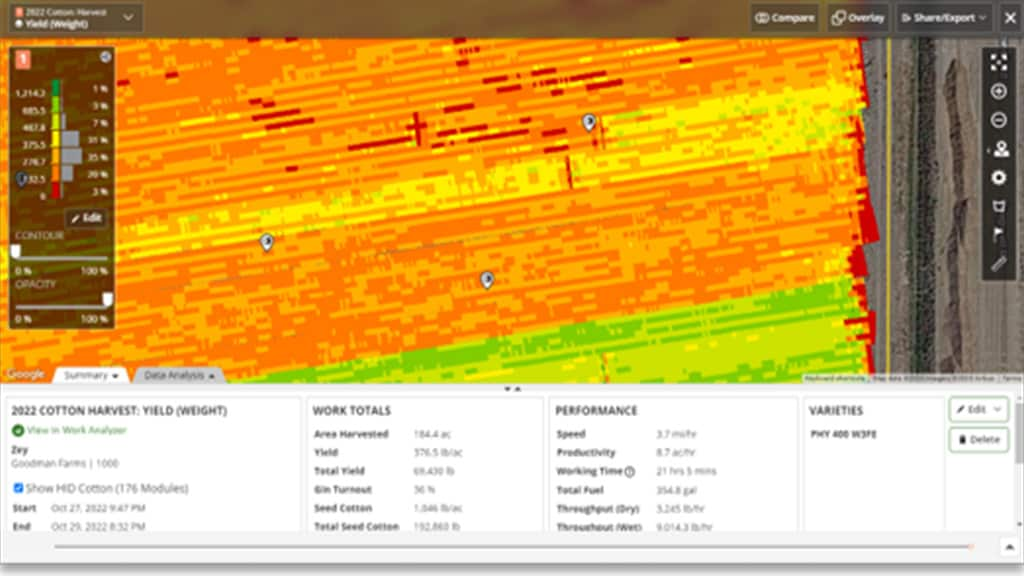

John Deere Operations Center™

Access field, crop, and machine information anytime on your desktop computer or mobile device through your John Deere Operations Center™ account. Plus, with many connected software tools, including major farm management systems, you can make the most out of your data.

Harvest Identification, Cotton Pro

Capture, analyze, and share harvest information down to the module with Harvest Identification, Cotton Pro. Track module moisture and weight, then share that information with your gin to help prioritize module movement. Together, Harvest Identification, Cotton Pro allow for traceability from field to end use.

AutoTrac™ RowSense™

AutoTrac RowSense system keeps you on row. All of our cotton headers come standard with RowSense in base equipment to closely follow the cotton rows with less operator effort. Teamed with the available technology packages on our C770 Cotton Harvesters, AutoTrac RowSense provides an extra level of guidance to make sure that the harvester is always on row, no matter the crop conditions.

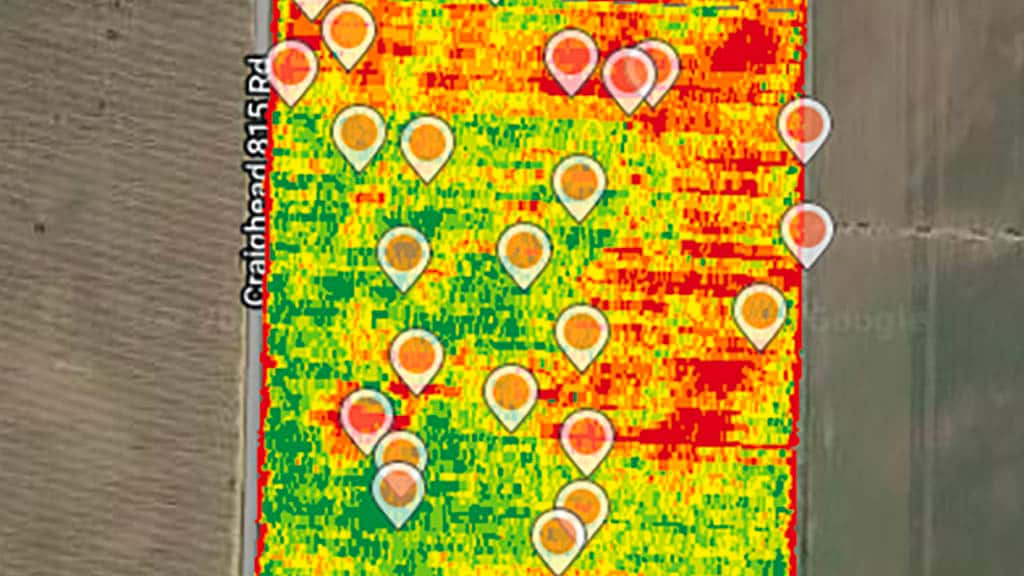

Documentation and Field Analyzer

Make informed decisions by reviewing your documentation data in Field Analyzer. Track your yields from field to field, then generate and share detailed yield maps with your consultants, seed reps, scouts or other advisors through your Operations Center account.

Row by Row Yield Documentation

With Row by Row, you can make data-driven decisions by analyzing documentation data right down to the row level. It also gives you real-time views of your yield, so you can spot opportunities to improve yield while you're harvesting.

Auto Flush

Focus more on your end row turns and less on flushing. With Auto Flush, simply set your desired flush length of time – and flush duration – and the system automatically flushes at the end of each row. That's one less task to worry about.

Auto Handler Raise

Auto Handler Raise is a software update that automatically raises the module handler after a module has dropped. That's one less manual task you need to worry about at the end of the row. It also reduces the risk of leaving the handler lowered, which can cause damage and downtime.

Accumulator Logic

Wish you could maintain ground speeds in higher-yielding crops? Now you can with this software update. It predicts when your accumulator is full or empty by using mass flow data and your existing sensors. It also minimizes the need to slow down during wrap eject cycle time.

Maintenance & Reliability

Our equipment is supported by one of the most responsive dealer networks in the business.

John Deere Connected Support™

Cotton Harvesters come with built-in technology to sense potential issues and alert you - or your dealer - when there's a concern. With Connected Support, you get Remote Display Access and Expert Alerts. You can monitor machine fuel levels, location history, receive alerts and view the in-cab display remotely.

John Deere Protect Plans

Annual Expert Inspections and regular scheduled maintenance, coupled with PowerGard™ extended warranty will help ensure "like new" performance and uptime of your cotton harvester and reduce unexpected expenses for up to 36 months.

Inspections

Keep your cotton harvesters in tip-top condition with comprehensive inspections. The best-trained technicians in the industry will replace worn parts and tune up other key areas.

You Also May Be Interested In

Product Brochures

You May Also Be Interested In

1Internal John Deere comparisons between CP770 and CP690, and between CS770 and CS690. Individual results may vary.

2Only available on the CS770 Cotton Stripper.

3Compared to a John Deere CS690 when tested by the USDA Ag Research Service in Lubbock, TX.

4MP16’s 1.375-in (3.492-cm) space behind air door compared to MP16's 75-in (1.905-cm).

5JDLink hardware comes standard with the machine. You can turn on JDLink connected service in your John Deere Operations Center account for free. JDLink requires a cellular connection to transfer information from machine to Operations Center. Consult your John Deere Dealer for coverage availability.