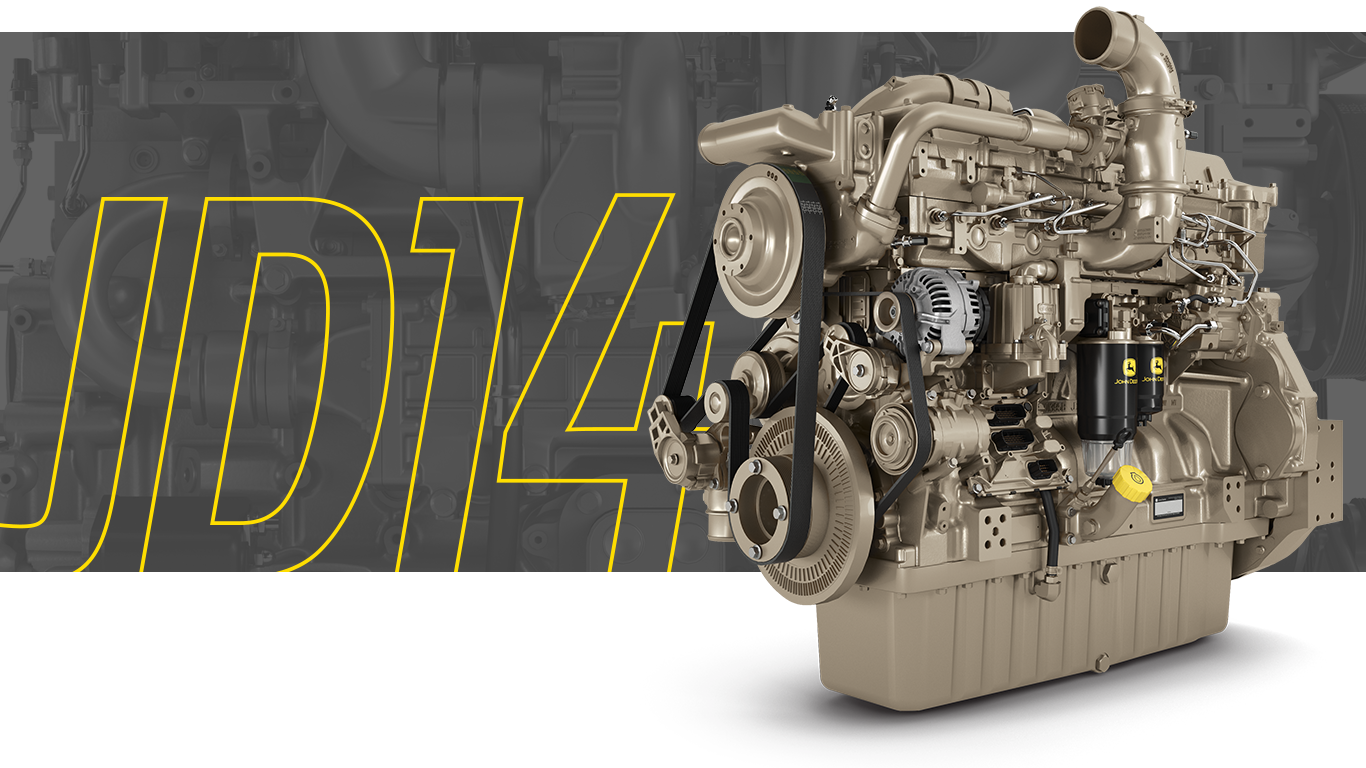

Connecting to Customer Needs: The John Deere JD14

The John Deere JD14 industrial engine is the culmination of more than 15 years of developing and refining effective engine design while keeping up with evolving emissions regulations. Having met the emissions regulations in both the EU and North America, we focused our resources on refining and optimizing these systems. With optionality and serviceability at the forefront, our engineering team took a high-level perspective to meet both customer and market demands with the JD14.

The power of choice

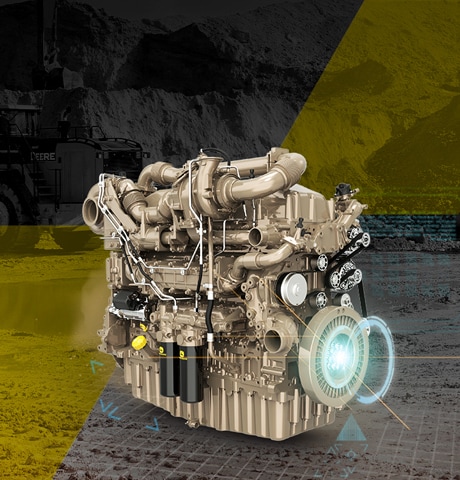

The JD14 features a reduced footprint for more space and less integration with similar displacement compared to its predecessor. This optimized engine size offers more power in a smaller package, which allows it to meet the needs for a wide array of heavy-duty applications. The engine also has the capacity for additional pumps with an integrated power take-off and multiple aux drive connections.

Part of reducing the footprint of the engine was switching the gear train location from the front of the engine to the rear, enabling more power from the rear. So with the JD14, you can lift from the back with rear gear train abilities, which also reduce engine noise and torsional vibration.

The in-line Integrated Emissions Control system of the JD14 offers 90 degrees of optionality. The choice is yours. It can be mounted horizontally or vertically, allowing the industrial engine to be compatible with more machines in customers' fleets while reducing connection points and optimizing thermal management.

No diesel particulate filter (DPF) is no problem with the JD14; having the option of no DPF increases the performance of your equipment and their overall fuel economy. Another decision you're empowered to make is between a single or dual turbocharger. Single turbo allows for higher power, ideal for high horsepower applications, while dual turbo manages lag and improves drivability for a more consistent power.

We wouldn't be successful if it were not for our relationship with John Deere and our engine distributor, as well as the performance of the John Deere engine product. The engines are just tried and true. They are dependable and they last.

John Deere Power Systems gives us great support in engineering integration and installation signoff.

Designed for ease of mind

Built to perform, the JD14 has reliability and durability at its core. However, John Deere understands that reliability is more than just horsepower — it involves designing this engine with ease of serviceability in mind. The JD14 engine is equipped with self-adjusting hydraulic lash adjusters (HLAs), eliminating the need to manually reset the valve lash — a lengthy service process. The next-generation engine control unit (ECU) eliminates the need for fuel cooling in all operating conditions. No fuel cooling also means no need for additional fuel lines and fittings, simplifying service processes that normally require removing the ECU.

The integrated wiring harness used in the engine design is tighter to the core engine and protects the wiring during assembly and service. The integrated design and reduced vibration improve reliability compared to engines that are designed with their wiring harnesses added around existing components.

With the JD14, you not only gain access to service-minded engine design and optimal performance, but you also have access to an entire service network dedicated to helping your business thrive. With more than 9,000 John Deere service locations worldwide, you do not have to travel too far to find expert assistance from a dealer.

JD14: More Options, Simplified Service

The JD14 engine was built to give you more customizability in your set up, with easier maintenance on the back-end.