More than just hot air – stopping frost in its tracks

One night of frost can spell disaster for fruit crops. Subzero temperatures can fatally damage leaves, buds, or even a whole generation of trees. Wind machines provide effective protection, but only when backed up with the right advice and service — something specialty firm GENER knows all about.

Since its creation in 2016, Turkey-based GENER has become the leading supplier of wind machines to farmers across Europe by putting service first.

"We deliver quality machines based on high-quality components," says Abdullah Ongen, co-owner of GENER. "We also have great partners, including John Deere and their distributor, TDMED, along with our own distributor network. And it's these relationships with our suppliers and our customers that are key to our success."

Keeping frost at bay with wind machines

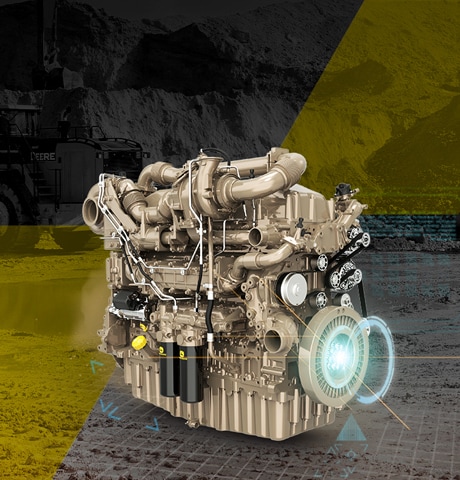

The company's wind machines consist of a propeller mounted on a tower with a John Deere industrial engine housed in a sealed cabin at the base. When temperatures drop below freezing, the propeller spins and mixes layers of colder and warmer air — preventing frost from forming on the trees.

The towers are typically installed in permanent locations throughout an orchard, although portable versions are also available. For farmers with trees that need protection at different times of the year, like citrus and apple trees, there is an option to optimize their investment through movable engine cabins that are designed to be moved from towers in one field to those in another.

Advice and service are key

The Ener family, one of the founders of GENER, knows firsthand the value of the technology; wind machines sourced from the United States helped save their crop during a particularly cold winter. In fact, it was this experience that inspired them to join forces with the Ongen family to distribute wind machines. The Ongens brought expertise in industrial production to the partnership.

As the two families worked together, they recognized what existing suppliers of wind machines were failing to provide — customer support.

"Farmers received no advice on how to get the most out of their machines, the best location and setup, the speed of the propellers, what to be careful of, and more," Ongen says. "So we thought, let's go for it. We have the factory, the tools, and decades of farming experience. We know what growers need in terms of the machine and service."

No other engine supplier had ever offered us such an opportunity. Plus, seeing operations in person helped build trust and confidence in the John Deere brand and network, opening the way for a strong relationship.

Bringing John Deere and TDMED on board

Service was a crucial factor in the company's decision to move to John Deere engines in 2021. Frustrated by the lack of support from their existing supplier, they turned to John Deere distributor TDMED, who had just set up a branch in Turkey. John Deere engines were new to GENER, and tests with the John Deere 4.5L industrial engine proved successful.

"We like the 4.5L engine because it's a relatively simple mechanical and electronic engine that runs at constant rpm, which is ideal for this application," Ongen says. "Some of our distributors ask for 6.0L-type engines as they are common in this market, but we don't want to over-engineer and make our products more expensive than necessary. There's no need for the extra power."

Strong relationships and aftermarket support

Above all, GENER knows it can rely on TDMED for timely and accurate delivery from the distributor's base in Spain, as well as excellent aftermarket support.

"TDMED has become like family. They are knowledgeable and willing to learn," Ongen says. "We didn't need any modifications to the engines, but their application engineers helped with placing the engines on the foundations and in the cabin. TDMED also gives us the flexibility for the quantities we need."

In June 2021, John Deere and TDMED organized a visit to the John Deere factory in Saran, France, for a group from GENER and another major distributor in France who was uncertain about switching suppliers.

"No other engine supplier had ever offered us such an opportunity. Plus, seeing operations in person helped build trust and confidence in the John Deere brand and network, opening the way for a strong relationship," Ongen says.

Today, the company's S60 stationary wind machines are powered by 4.5L, 131 kW (175 hp) non-certified John Deere engines. These machines cover an area of approximately six hectares and represent the best solution for almost all farmers and field configurations.

GENER also offers a mobile wind machine powered by a John Deere 4.5L Stage V engine, and they have an order for a John Deere 4.5L, 105 kW (140 hp) Stage V engine for a new model in the pipeline.

Ongen highlights that in between sales, the TDMED and GENER teams remain in touch.

"Whether it's parts, repair, maintenance, or just talking about the market, these guys are always on standby with immediate assistance. It's a close and easy cooperation," Ongen says.

GENER currently markets its wind machines in Italy, France, and Eastern Europe, and is continuing to build its distributor network.

"As always, support is key. If we help our distributors to grow their business, and they do the same for our customers, everyone benefits and that's what makes for success," Ongen says.