(Re)power To You

Yacht owners bring a lot to the table: inspiration, vision, enthusiasm, a love of open water, perhaps combined with sailing expertise and an unparalleled knowledge of knots. But if they don't have engineering experience, repowering their treasure can be a nightmare. That's why finding a partner who can make the process smooth and easy is so important. For the Barattolo brothers from Rome, that role was ably filled by engine specialist Ambrogetti.

Ship in a bottle?

When a yacht is newly built, engines and other systems are usually installed while the hull is still open. But that means that removing the marine engine and installing a replacement during a repower can be as tricky as deconstructing and reconstructing a ship in a bottle. It's a challenge the Barattolo brothers faced with their 54-year-old Artemisia.

While Artemisia was structurally in good condition, it needed refurbishment and new engines. The brothers gladly handed over the entire marine repower to Ambrogetti, a company that delivers highly customized, ready-to-drop-in engines and full integration support. "We're no engineers and had no idea where to start," the brothers said. "We knew Marco (Ambrogetti) and trusted his team's expertise and integrity to choose and install the most appropriate and cost-effective solution for us."

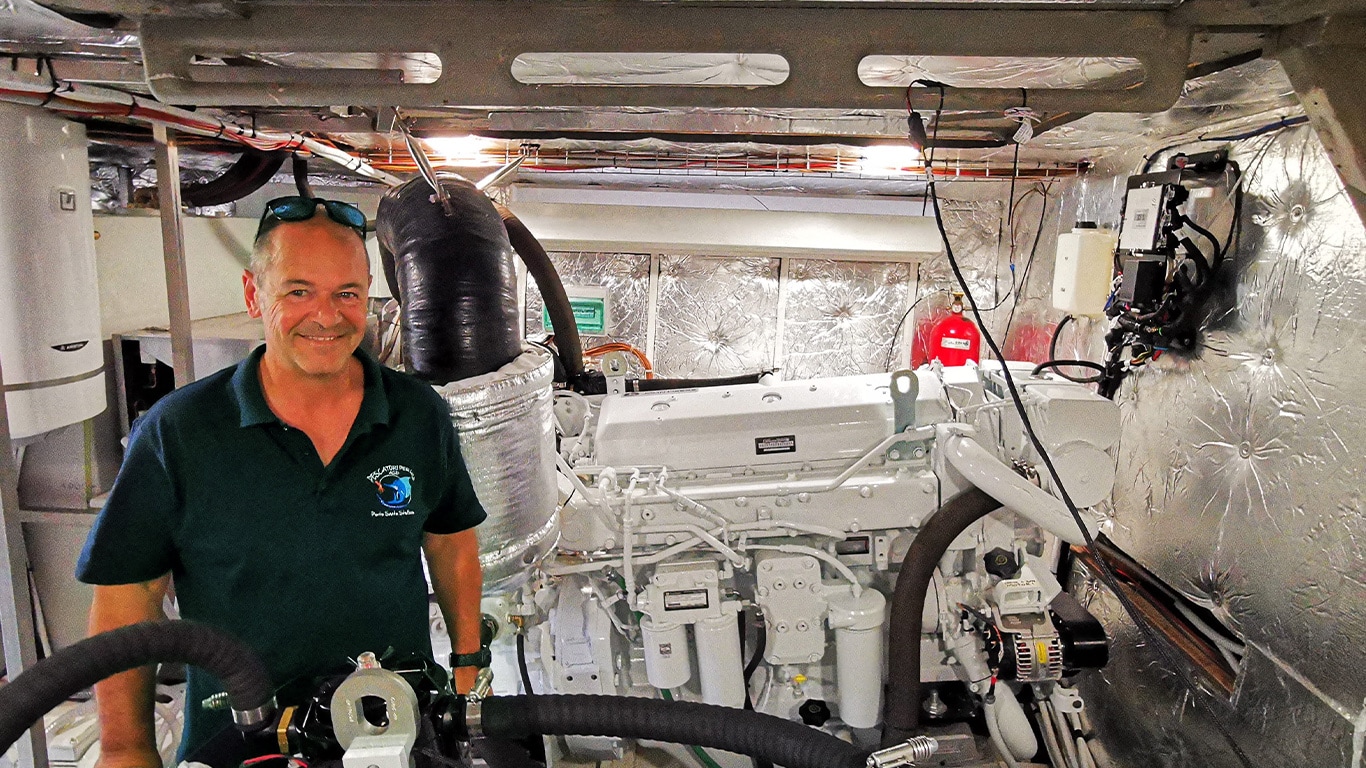

Marco Ambrogetti is the second generation to run the Ambrogetti company, which was founded in 1964 by his father, Luigi. Today, the family company has a staff of 10 and specializes in on-board mechanics and systems, including engine installation, overhauls, repairs, and spare parts. From its headquarters in the Tuscan seaport town of Porto Santo Stefano, the team provides 24/7 support to both private and commercial customers.

The right repower fit in a tight fit

Pleasure craft owners in particular rely on Ambrogetti's full-service support and engineering expertise. As Ambrogetti describes it: "This can be anything and everything from choosing the right power source and components to determining the best engine room setup and connecting everything to trials and certification. Engine rooms can be tight, so it's crucial we install an engine that has the right power-to-size ratio yet allows the space for easy maintenance. Where possible, we try to use the existing shaft and propeller because it keeps the original look and is also more cost-effective."

Since 2011, Ambrogetti has been part of the dealer network of Rama Motori S.p.A, the John Deere engine distributor for Italy and the Balkans.

"John Deere delivers reliability, strength, and simplicity, which makes the marine engines easy to maintain," Ambrogetti says. "It's our brand of choice when the customer is looking for a low-maintenance, fuel-efficient engine."

Refurbishing Artemisia: 54-year-'young'

To breathe new life into the 18-meter (59-foot) yacht, the brothers had the wooden panels and floors sanded and repainted, electricity rewired, and a new generator installed to power all on-board electricity.

The propulsion system was no longer working and needed a complete replacement: from shaft and propeller to the two original 6-cylinder, 12-liter (3.7 gallon) engines.

Ambrogetti took the lead, starting by identifying the best propulsion system for the yacht.

"Choosing the right marine engine begins with clarifying how the owner will use the boat and then determining the best power/size ratio," Ambrogetti says. "The owner plans to cruise around the Mediterranean and will probably clock around 100 to 150 hours a year. So, we proposed two John Deere 559 kW (750 hp) 13.5-liter engines with the same power capacity as the original engines. They won't put any pressure on the boat's structure and will provide the fuel efficiency, low noise, and long engine life the Barattolo brothers want."

Complete engine packs simplify integration

Rama delivered the marine engines already assembled with a cooling package (radiator, pipes, tubes, and supports), air filter, pump drives, and electronics. The engineers connected the engines to a new drive shaft and propeller of the same brand as the originals, and to a new engine monitoring display.

Since 2021, Rama has been customizing and assembling John Deere engines from its own in-house production department, offering customers design flexibility and quick delivery.

"There's no one-size-fits-all in the marine industry, and marine engines are quite different from industrial engines," Ambrogetti says. "For example, they have a shorter expected duty cycle than their industrial counterparts, but they operate at constant high speeds and lower rpms for a short period of time. Plus, they're more vulnerable to corrosion. In addition, they need extra features to prevent them from catching on fire — which is life-threatening on board a ship. Everything from starters, alternators, and distributors to gaskets, housings, and plugs is designed to avoid corrosion. It's a lot to deliver, but John Deere marine engines hit the mark."

In June 2022, Ambrogetti and Davide Giuliani, Service & Training manager at Rama, took the repowered Artemisia out for a trial run.

"At 2250 rpm, it reached a maximum speed of 29 knots. At cruising speed —– 25 knots —– each engine consumed 80 to 100 liters (21 to 26.4 gallons), and vibration levels were good. We're very pleased with these results," Ambrogetti says.

Since 2021, Rama has been customizing and assembling John Deere engines from its own in-house production department, offering customers design flexibility and quick delivery.