Nothing To Prove, Everything To Improve

This compact, high-capacity 962 Venturi tracked side loader has a chip diameter capacity of up to 65 centimeters (26 inches).

What happens when you look at a product and realize, "I could make it better"? If you are Dutch engineer Jippe Ufkes, you just do it! In 2009, Ufkes switched from selling imported woodchippers to building and distributing his own. Today, Ufkes Greentec chippers are appreciated worldwide for their ease of use, high quality, and high return. All benefits that are further supported by the John Deere industrial engines powering the units.

Staying with the John Deere brand

"Most of the chippers I imported had John Deere engines," Ufkes explains. "I liked them because they never had any issues processing different types and thicknesses of materials. In addition, no matter where our customers were located, they received expert engine service. So, I was keen to stay with John Deere, but through a local supplier. I contacted NPS Driven B.V., a John Deere engine distributor for Benelux, France, and Germany, who had provided service for some of our engines over the years. I trusted them."

High quality, high return on investment

"As a sales engineer, I saw the limitations of the chippers we imported," continues Ufkes. "It was clear to me that with a few smart, simple changes, we could offer a highly efficient, dust-free, and easy-to-use woodchipper with great ROI potential. Even now, we constantly challenge ourselves to combine simplicity and smartness in our designs."

Ufkes Greentec's extensive range covers more than 40 chipper designs, including track-mounted, hitch-mounted, PTO-driven, and self-propelled woodchippers with infeed openings from 30 to 90 centimeters (12 to 36 inches).

The company's Parkline and Forstline product lines cater to different customers and application needs. Parkline meets the needs of arborists, municipalities, and landscaping companies for smaller-capacity machines. Forstline offers larger-capacity versions for foresters, contractors, and tree care companies. A modular design approach enables quick customization for customers' needs, which is very unusual in the woodchipper equipment business, according to Ufkes.

The Greentec difference

Ufkes Greentec chippers feature a Venturi discharge mouth and integrated blower system to powerfully discharge chips. Cutting material at the front and discharging chips at the back reduces dust in and around the machine, making the chippers especially popular for urban jobs. Four program settings enable them to handle anything from branches to heavy logs, and an eco-mode lowers the engine's rpm by 15%, reducing fuel consumption and noise. A cost-efficient, quick-change, disposable knife system speeds up knife replacement, keeping work moving. And a specially designed sieve ensures dust-free delivery of a clean, uniform chip size. Ufkes Greentec's Control System 3.0 (GCS) allows the operator to monitor and remotely control the machine, crane (if applicable), and John Deere engine.

Cutting at the front of the machine and discharging chips at the back reduces dust in and around the machine, making the chippers especially popular for urban jobs.

962 Venturi tracked side loader

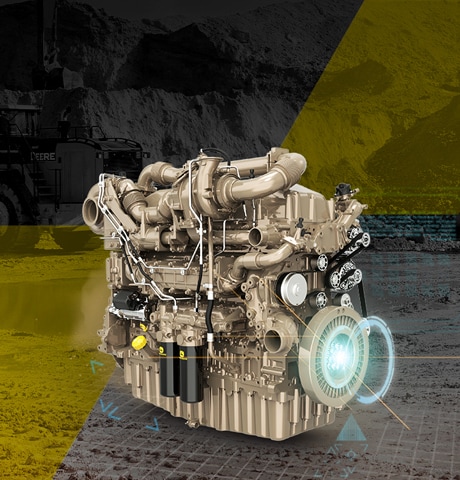

One chipper that showcases the best Ufkes Greentec has to offer is the 962 Venturi tracked side loader. This compact, high-capacity powerhouse has a chip diameter capacity of up to 65 centimeters (26 inches) and is powered by a John Deere 9.0L Stage V engine.

The extra-wide infeed table with a 96-centimeter (38-inches) diameter processes extremely tough offshoots and splits, thanks to the Venturi/blower system combo. The large drum chipper easily handles trees, logs, and branches, even when the knives start losing their edge. A specially designed counter knife cuts fine branches at a different angle, enhancing cut quality and yields.

Ufkes Greentec replaced the traditional single, large infeed roller with two smaller top-infeed rollers fitted with sharp teeth. This allows the blades and rollers to hold onto the log longer and delivers more uniform chips with less strain on the machine. The bottom roller is placed at a high angle which, in combination with the sharp teeth, draws branches in better. The top roller makes light work of even thick logs.

Running at low rpm, the John Deere 9.0L industrial engine can easily switch between materials. "No matter what material the operator throws at it, the engine runs quietly and consistently," says Ufkes.

NPS Driven: No loose ends

The large-capacity, self-propelled 942 and 952 mega chippers are also powered by John Deere industrial engines: 6.8L and 9.0L Stage V engines respectively.

"They deliver reliability, flexibility, fuel efficiency, and low noise," says Ufkes. "Within each program, the operator can adjust start and stop speed, infeed speed, infeed rollers, and engine speed to handle even the most extreme loads. This puts a lot of demand on an engine, but the 6.8L and 9.0L can handle it."

All engines are supplied by NPS Driven.

"NPS shares our work ethic: deliver on your promises, focus on solutions, and don't leave loose ends," Ufkes says. "We involve them in the development of new models, and they provide us with 'plug and play' power packs that we can simply drop in. In Dutch we say 'het klopt,' which basically means 'everything's just right.' Their support continues after integration. NPS technicians are always on standby and quick to respond."

Future ambitions

Ufkes has serious ambitions for Ufkes Greentec.

"We have begun designing our largest-capacity chipper, which we intend to power with a JD18 engine," Ufkes says.

He expects demand for Ufkes Greentec's self-propelled chippers to increase.

"In Europe, contractors are switching from PTO-driven to self-propelled chippers, and in the U.S., customers are learning to appreciate our machines' smart efficiency," Ufkes says. "We will be setting up a service point there to support customers with customized products, too."