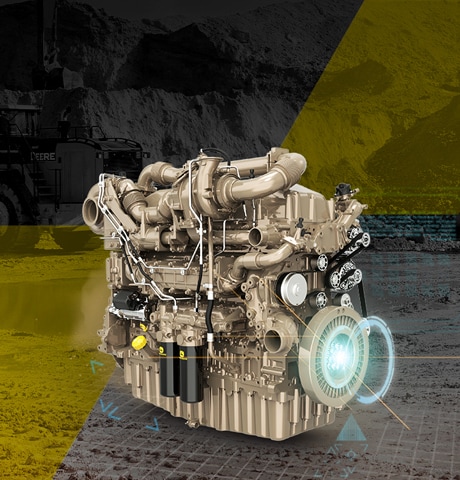

Going Electric With John Deere

⠀

Current and anticipated regulatory actions are accelerating a trend toward sustainable electrification solutions for the off-highway equipment industry, which is expected to grow at a rate of more than 4.7 percent annually over the next five years.

Why Electrification for Off-Highway Equipment?

With an industry-wide acceleration toward electrification, John Deere has set impactful sustainability goals for 2026 across its different manufacturing segments that are focused on developing battery power solutions to serve as sole or hybrid propulsion systems for off-highway equipment and vehicles. John Deere sees a growing demand for battery power solutions for off-highway equipment and vehicles as more countries establish regulatory requirements around emissions.

- European Climate Law requires 55% lower emissions by 2030 and net zero emissions by 2050; current emissions standards call for a 37.5% reduction for cars and 30% for trucks by 2030.

- The U.S. has set a goal of reducing net greenhouse gas emissions by at least 50% by 2030.

- And in South America, most countries have established deadlines to attain carbon neutrality; Chile, Brazil, and Mexico have launched plans to electrify their auto industries by 2040.

These emissions regulations are highlighting the need for diversified powertrain solutions that can meet power requirements across a range of equipment sizes. In response, John Deere is prioritizing a holistic approach to its power offerings by making strategic investments in electrification, alternative fuels, and other future-forward technologies that will give OEMs and their customers a competitive edge in the off-highway market.

Within its electrification strategy, John Deere is prioritizing the electrification of equipment that is most impacted by current and anticipated regulatory actions. This includes equipment that could rely solely on batteries as a primary power source such as turf equipment, compact utility tractors, small tractors, compact construction equipment, and some road building equipment.

Get To Know Kreisel Electric Inc.

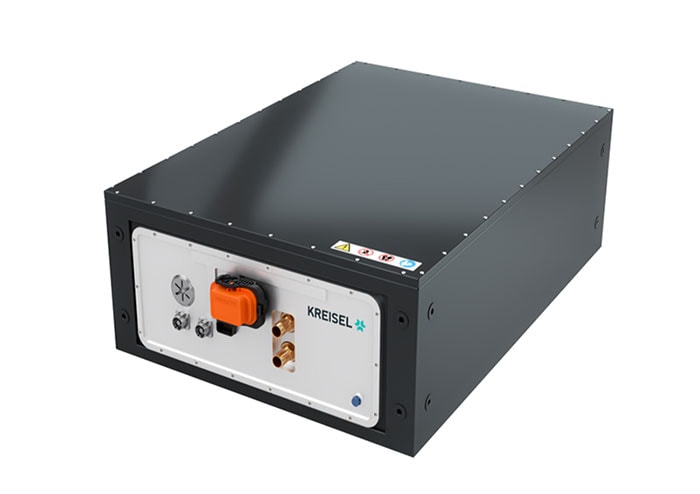

To better support OEMs in meeting their electrification goals, John Deere recently acquired majority ownership of Kreisel Electric Inc. (Kreisel), a battery technology provider based in Rainbach im Mühlkreis, Austria.

Kreisel develops high-durability electric battery modules and packs and has also developed a charging infrastructure platform (CHIMERO) that utilizes this patented battery technology. The company is a pioneer in the design, validation, and manufacturing of battery modules and packs in the emerging space of off-road electrification. Kreisel serves a global customer base across multiple end markets, including commercial vehicles, off-highway vehicles, marine, charging infrastructure, e-motorsports, and other high-performance applications.

The current global energy market is calling for sustainable and efficient battery solutions. With the dedicated support and extensive expertise of John Deere, Kreisel answers the call by providing battery technology that offers exceptional lifetime, safety, and performance for its customers and stakeholders.

With an experienced team and prioritization on research and design, Kreisel is developing differentiated, modular battery products that offer high performance, durability, and advanced safety features. Designed to offer superior safety, Kreisel batteries utilize immersion cooling technology for best-in-class thermal management to ensure that the battery’s cells operate in a perfect temperature range for a prolonged battery life.

Kreisel targets applications with demanding duty cycles and high operating hours, making their products a good fit for John Deere manufacturing segments: agriculture, construction, road building, commercial mowing, and golf applications.

Kreisel batteries are also designed to be durable and offer maximum flexibility with the ability to be scaled into thousands of combinations of voltages, energy capacities, and powers. This modular approach helps to reduce costs and increase compatibility for John Deere OEM customers.

Kreisel's plug-and-play fast-charging device (CHIMERO) will play a significant role in developing the robust charging infrastructure needed for a successful transition to battery power in the off-highway industry. CHIMERO utilizes Kreisel's patented battery technology to provide electric vehicles and equipment with high-power charging without straining the grid.

The investment in Kreisel helps to accelerate the progress John Deere is making toward integrating battery-powered equipment across a range of segments as demand in the off-highway industry continues to grow.

The Future Isn't Just Bright, It's Electric

Looking to the future, John Deere and Kreisel will work together to accelerate the development of Kreisel technology and leverage the learning along the way to design and build the best possible products for customers. With its established remanufacturing capabilities, John Deere also has the potential to expand into electric powertrain remanufacturing and battery re-life to lead the way in the off-highway electric vehicle circular economy.

It will take a variety of power sources to meet the unique needs of off-highway equipment applications, and building an electrified portfolio is key to the company's sustainability goal of pursuing progressive technologies that reduce the environmental impact of new products.

Kreisel's innovative technology — combined with John Deere design expertise, global manufacturing presence, and strong supply base — will create a compelling option for OEMs working to electrify their equipment to keep up with the changing world.