Ensuring road safety from A(lpha) to Z

More than 100 Deere-powered Alpha tool carriers are already working worldwide.

Some things are just made to go together — the clock radio, the seaplane, the smartphone. These are all examples of how combining two or more ideas can create new, efficient, and even ubiquitous products. That was the vision Energreen, in Italy, had in mind when it developed Alpha: its award-winning, self-propelled hydrostatic tool carrier for roadside, mountain, and concrete overpass vegetation control.

A tool carrier for all seasons

Alpha unites a lightweight, hydrostatic tractor with a large range of attachments that cover a myriad of applications. This makes it the single solution for detailed work in challenging spots, such as forest edges, mountainsides, concrete overpasses, and even around highway signs. The all-season equipment helps keep roadways safer and increases driving visibility through year-round mowing, springtime brush control, summertime and autumn tree removal, and wintertime snow blowing and road salting.

For Alpha's design, Energreen took the capabilities of a tractor, shredder, and mower — traditionally used for more heavy-duty forest applications — and combined them into one machine with three T-shaped booms from 8 to 12 meters (26 to 39 feet).

Exceeding customer expectations

"We started our design around the key needs of our customers: long reach, great visibility, hydraulic performance, and ample cooling — which is a major challenge, especially when using a mower," said Daniele Fraron, managing director and shareholder at Energreen. "But thanks to the John Deere engines, we have this covered."

Fraron has been a huge fan of John Deere since childhood and is delighted the engines have proven to be the perfect fit for both Alpha and its big sister, Athena, which packs a bit more power. It's ideal for working around canals or steep hillsides.

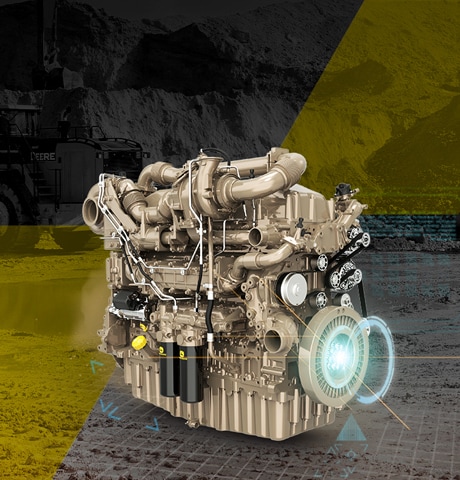

The Alpha is powered by a John Deere 129-kW (173-hp) 4.5L Stage V engine. The complete package is supplied by Rama Motori SpA: the John Deere Power Systems engine distributor in Italy. It includes a large radiator, separate lubes for hydraulics, and reverse fan operation. This has increased the tool's cooling performance, making it suitable for hot conditions and sub-zero environments.

"The John Deere engine delivers fantastic torque (1500 rpm), fuel efficiency, and performance in a compact package," Fraron said. "Our customers appreciate how the engine kicks in immediately when they need it. In one day's work, they may have to handle short grass, tall grass, bushes, steep hills, and more; which means the power requirement fluctuates constantly. The John Deere engine always responds perfectly."

The slightly more powerful Athena offers a 15-meter (59-foot) boom and is driven by a John Deere 168-kW (225-hp) 6.8L industrial engine. Both units can reach 24mph (38.6 km/h) and can be operated by a single person. And changing attachments only takes 15 minutes.

The 4.5L engine delivers fantastic torque, fuel efficiency, and performance.

Tool carriers designed for visibility and safety

The other unique characteristic of the design is the optimal visibility, which increases operational safety, says Fraron. The patented cab design guarantees 180-degree visibility of the working area. With the ability to rotate up to 90 degrees, the operator can work both sides of the road without moving the machine or straining their neck. Energreen received an innovation award for its rotating cabin concept on a vegetation control vehicle at the international SIMA exhibition in Paris in 2008.

"Rama was a huge help for making this increased visibility and safety possible. They reconfigured the engines and moved the emission reduction technologies to a different position, which allowed us to reduce the size of the tail," Fraron said. "We can now offer one of the most compact tool carriers for this kind of work on the market."

Fraron is extremely pleased with the hands-on support that Rama offers. "Rama staff are very experienced and passionate about what they do. They're always available to help. When a customer wanted to replace his old John Deere engine with the same model, Rama found and delivered it within a few days. And in addition to the official training for us and our customers, they take the time to explain the ins and outs of John Deere technologies to our engineers."

Energreen's Alpha hydrostatic tool carrier with 4.5L is ideal for roadside work.

Expanding horizons

In 2021, Energreen purchased more than 100 John Deere industrial engines: most of these are already installed and at work. Another order for more than 120 has already been placed, as the company is ramping up production of both Alpha and Athena to meet the strong demand of the U.S. market.

"We recently opened a branch in the U.S. and we see a lot of potential. Americans are open to doing things differently: in this case, switching from multiple machines to a single solution in urban areas. And in this key market, the solid reputation of John Deere will certainly help," Fraron said.

Mutually beneficial relationship

The collaboration between Energreen and Rama has proven beneficial for both companies.

"The contract with Energreen has spurred our move to in-house assembly and customization of John Deere engines," said Enrico Menozzi, product manager at Rama Motori. "This supports our commitment to delivering consistent quality, highly customized engines, and on-time delivery to all our OEM customers."

The John Deere-powered self-propelled tool carriers clearly have a bright future. Already more than 80 Alphas are out in the field across the globe.

"The combination of Rama's service and John Deere engines give us and our customers exactly what we need, plus worldwide support. The next step is to fit smaller John Deere engines for our Aspen and Kommunal units," Fraron said.

Surely a match made in (road safety) heaven!

Energreen's robot remote control units for clearing inhospitable terrain are another market first. The fully encapsulated, completely steel design is extremely popular and comes in five versions. The track-tired RoboGreen, for example, can maneuver along 55-degree embankments.