Breathing New Life Into Old Favorites

Emma, Petersen Tegl's clipper-like wooden sailing ship, is a remarkable sight in the Flensburg Fjord near the company's headquarters.

The history of Denmark-based manufacturer Petersen Tegl's bricks is closely associated with sea trade. It's a link that CEO Christian Petersen strengthened with the purchase of Emma, a 90-year-old clipper-like wooden sailing ship. And just like Petersen bricks breathe new life into historic buildings, a John Deere 6.8L engine helped to revitalize Emma. Now, the ship helps Petersen Tegl spread the word about design and quality by hosting customers visiting the brickworks.

A story of rum and ballast

Petersen Tegl, a manufacturer of specialized brick and tile products based in Broager, Denmark, is a family-run company that was founded in 1791. In the early days, the company played a rather unusual role in the rum and sugar trade: after unloading their cargo in Europe, they would fill the ships' holds with Petersen Tegl bricks as ballast for the return voyage. On arrival in the Caribbean, the bricks were then used to build houses.

Today, Petersen Tegl bricks give class and spirit to new builds and restorations. Popular designs include the world-famous Kolumba™, developed for the Kolumba Museum in Cologne, and the Petersen Cover™, a tile product for covering roofs and facades. The company works closely with architects, builders, and artists to develop the "perfect brick" for their designs.

In another example of the personalized service Petersen Tegl is known for, visitors are able to take tours around the factories and the local fjords aboard Emma.

Making waves with Emma

Petersen originally bought Emma in 1971 for his summer holidays. But in 1992, he began using the ship commercially to strengthen relationships with potential customers.

"Lunch on Emma is the perfect wrap-up to a visit," says Mikael Dorow, representative of Petersen Tegl. "We share the history of our company and area, and the relaxed atmosphere can even trigger interesting innovations, including a new brick color based on a combination of red wine and milk!"

West Diesel ticks all the boxes for a marine engine repower

In 2021, Petersen decided it was time to replace the marine engine he had fitted soon after buying the vessel.

"We had some hard-to-fill requirements, however," explains Dorow. "As moisture can be an issue on wooden boats, we were looking for a mechanical engine without a lot of electronics. We also wanted a partner with experience powering a wooden boat who could also run everything for us. There aren't many local companies that could fulfill our requirements, so we were delighted to find West Diesel A/S, the John Deere engine distributor for Denmark!"

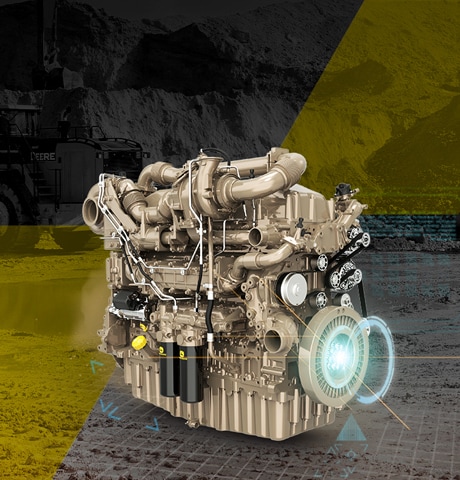

Rasmus Sørensen, sales manager at West Diesel A/S, took the men to a nearby port and showed them a similar boat fitted with a John Deere 6.8L mechanical engine.

"The owner was very pleased with its performance, and we were impressed with the low vibration levels," Dorow says. "Being able to see the engine in a similar application helped us make an informed decision, and we instantly knew West Diesel and John Deere were the right partners for us."

The perfect fit, installed in a day

The marine engine repower took place at local C.J. Ship and Boatyard, where the wheelhouse and fuel tanks were replaced and the old engine was removed. Two technicians from West Diesel then took measurements to ensure that the power pack could be installed quickly and with the right foundation.

West Diesel prepared the complete package in its workshop, including engine mounts, fuel lines, and crankcase ventilation. The team then worked with the shipyard to install everything. In fact, once the wheelhouse was removed, engine installation was completed in just a day.

Work on Emma started in January, and by mid-March it was back in the water and ready for new adventures. The engine drives a Dong gearbox with a ratio of 3.46:1, the original 3-blade propeller, and the fire pump that is mandatory now that Emma is a passenger vessel.

"We were impressed with how quick everything was wrapped up, as well as with the low vibration of the engine," Dorow says. "In fact, the entire experience with West Diesel A/S has been extremely positive. They invested considerable time and effort to make us feel comfortable about our decision."

Seamless repower service for a smooth ride

"The John Deere difference is not just the product; it's the entire customer journey, navigating the customer from A to Z quickly and seamlessly," says Sørensen. "As Petersen has no tech engineers, we will take care of all maintenance and service."

Repowered Emma is currently taking guests to visit the Flensborg Fjord and local waters three to four times a week.

"She doesn't run many hours, but these lunch trips have definitely become more comfortable and pleasurable for us and our customers," Dorow adds.

In the meantime, C.J. Ship and Boatyard has begun building a similar vessel for a German Petersen Tegl customer who was present when the John Deere engine was installed in Emma and who was very impressed with the process. The power source of choice? A 6.8L John Deere engine, of course!