Flow Control

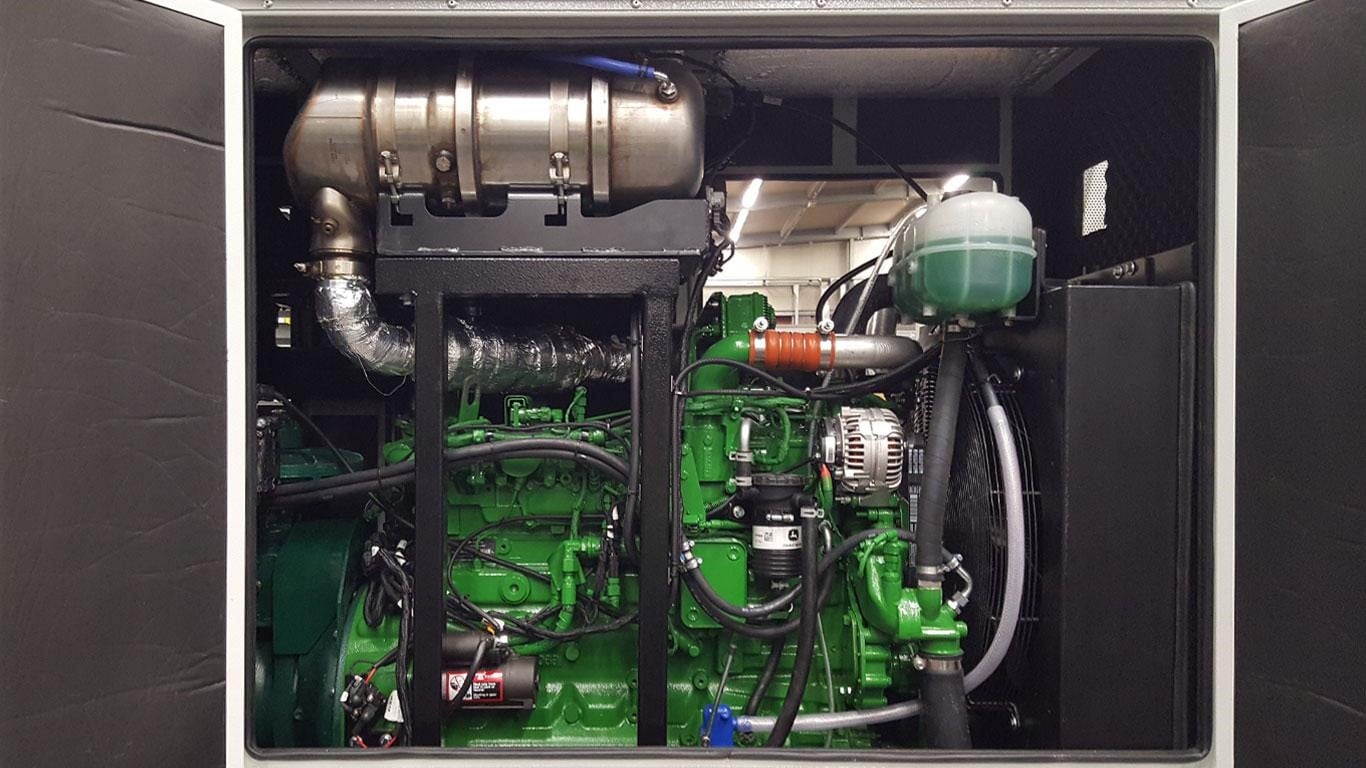

Moving aggressive, corrosive, solid-laden fluids is an ever-increasing challenge for process plants. It's a job best left to expert fluid handling companies and a specialized pumping solution such as the JP200 self-priming process pump built by Idrofoglia. Customized for a U.S. buyer and powered by a John Deere PowerTech™ 6.8L Final Tier 4 variable-speed industrial engine, it tackles the most abrasive fluid applications while keeping operating costs down and minimizing wear.

Keeping businesses flowing with customized pumping solutions

Founded on 40 years of supplying more than 100,000 installed pumps worldwide, Italy-based Idrofoglia's process pumps are tried, tested, and proven to deliver in agricultural and industrial applications. The heavy-duty JP200 pump was customized for testing new industrial fluid piping systems in the U.S.

The JP200 pump offers a capacity of approximately 650 cubic meters (22,954 cubic feet) per hour. With a flow rate of 360 cubic meters (12,713 cubic feet) and a pressure of 5 bar, the pump is capable of moving a wide range of fluids, including water, acidic chemicals, wastewater, petroleum, oil, sludge, abrasive slurry, and food. The pumping unit and 350-liter (92.5-U.S. gallon) fuel tank are mounted on a fixed frame. Easy access to hoses and the impeller speeds up maintenance and parts replacement.

John Deere is a historic brand, valued worldwide. The engines are powerful and efficient, and the support network is reliable. Both the engines and Rama have played a major role in the success of our pumping solutions.

Variable speed engine means more control

Idrofoglia likes to use variable-speed engines in its pumping solutions because they give operators more control over the process. “To remain competitive, fluid-handling companies must keep the total cost of ownership of their pumps down while maximizing their uptime,” explains product manager Michele Pretelli. “Using variable-speed engines can help achieve this balance. By configuring the right pump speed for each application, companies can reduce the number of pumps in the fleet while decreasing fuel costs and equipment wear.”

For more than two decades, Idrofoglia has relied on the proven performance and fuel efficiency of John Deere variable-speed industrial engines in its Fox and Turbo range of 60 to 186 kW (80 to 250 hp) motor pumps. For the customized JP200, Idrofoglia transitioned to Final Tier 4. Italian engine distributor Rama Motori S.P.A. recommended and supplied the John Deere PowerTech PVS 6.8L.

This larger engine required some changes to the usual pump setup, so Rama and Idrofoglia engineers worked together to ensure a perfect fit. “We then tested the pumps thoroughly to ensure that the Final Tier 4 engines maintain the proven performance customers expect from our pumps,” Pretelli says. “We are very pleased with the final product we supplied.”

“John Deere is a historic brand, valued worldwide,” Pretelli adds. “The engines are powerful and efficient, and the support network is reliable. Both the engines and Rama have played a major role in the success of our pumping solutions. Rama’s knowledge about our industry and our products is impressive. They really understand our market and know instinctively which engines will provide the best results for our clients.”

The U.S. customer needed the two JP200 pumps on very short notice. This was no problem for Idrofoglia’s lean manufacturing process and committed engine supplier Rama Motori. “Customer satisfaction is a priority and goes well beyond customization of our products,” says Pretelli. “It means keeping in close touch with our customers and offering them first-class packages, value for money, comprehensive care, local service, and all the backup they want.”