TOL Incorporated knows how to rise to the occasion. Especially when it comes to manufacturing pruning machines to support the ever-changing needs of the orchard industry.

Leveraging more than 40 years in the design and manufacture of orchard equipment, TOL continually seeks new technologies and designs to boost the productivity of its orchard equipment.

When a California orchard grower approached the company to design and manufacture a self-propelled pruning machine with more cutting capability, TOL took on the challenge. They went to work to develop a new dual-boom hedger, the HD1800RM, in just eight months.

"One of our greatest strengths is our ability to quickly adapt to the changes in the industry," said Scott Hermann, general manager of TOL Incorporated.

Rising to the challenge

TOL works closely with its John Deere engine distributor, Western Power Products. When it came time to adapt to the newest industry change for orchard equipment — Final Tier 4 emissions standards — TOL knew its John Deere distributor would go above and beyond to ease that transition.

"We requested that engineers from Western Power travel to our manufacturing facility in Israel, and we are very grateful for their assistance," said Hermann. "This was extremely helpful and saved us a lot of time and money."

Solutions-oriented results

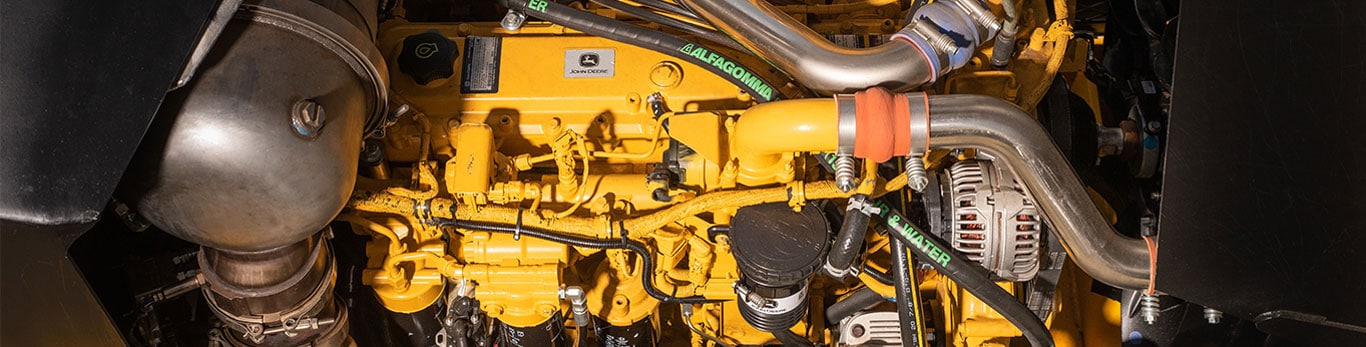

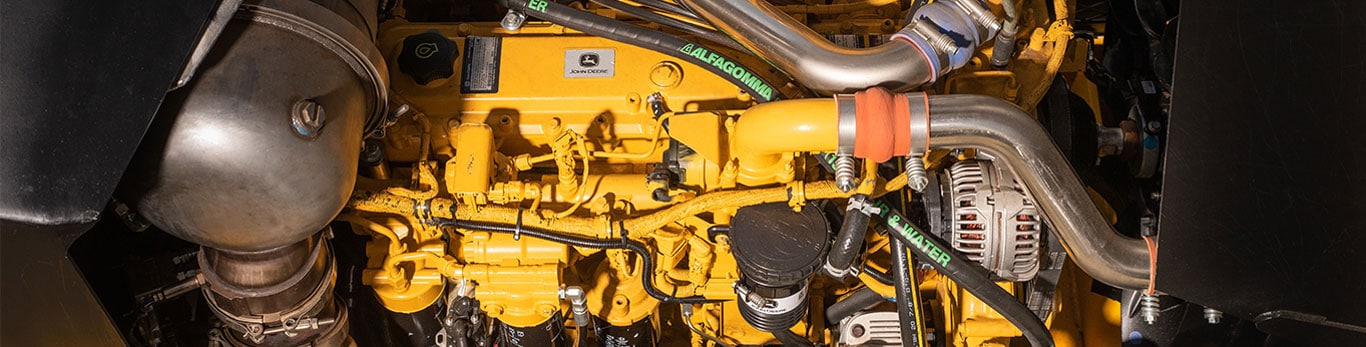

The new HD1800RM is hydraulically powered by a PowerTech™ PVS 6.8L Final Tier 4/Stage V engine and Funk™ Series 28000 pump drive. In addition, the machine's engine cooling system was engineered by TOL with guidance from Western Power Products.

"On our machines, the cooling system is very complicated. We prefer to have our cooling package at the back of the machine while the engine sits at the front of the machine. This posed some challenges for the Final Tier 4 engines," said Hermann. "The engineers at Western Power helped us accomplish this goal by providing necessary guidelines to help our designs meet the engine requirements, and they ensured that the engines would operate efficiently and reliably."

TOL's relationship with Western Power has been nothing short of wonderful, according to Hermann. "So far, we have had no problems with the Final Tier 4 engines, and that would not have been possible without the support of the engineering team at Western Power. We spent several years working on it to make sure we had everything correct."

We requested that engineers from Western Power travel to our manufacturing facility in Israel, and we are very grateful for their assistance. This was extremely helpful and saved us a lot of time and money.